Features

Small package with high efficiency ,

Low voltage operation, Instant light ,

Long operation life

Lead free product ,

RoHS compliant

Applications

Mobile phone flash

Automotive interior lighting

Automotive forward lighting

Architectural lighting

LCD TV / Monitor backlight

Traffic signals

Task lighting

Decorative/ Pathway lighting

Remote / Solar powered lighting

Household appliances

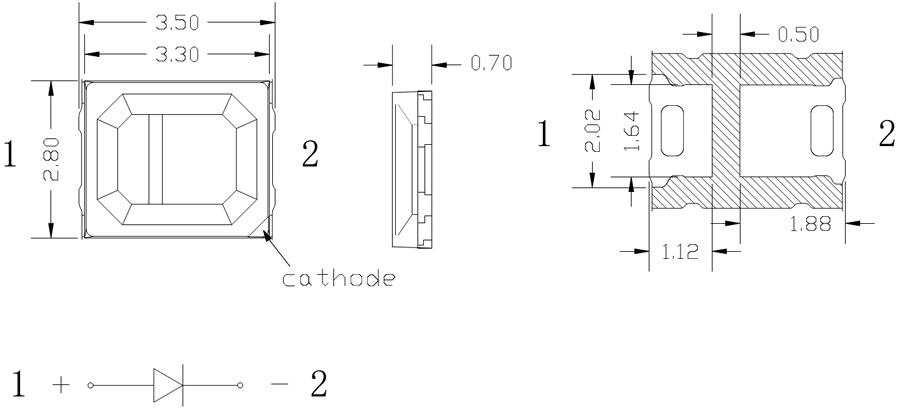

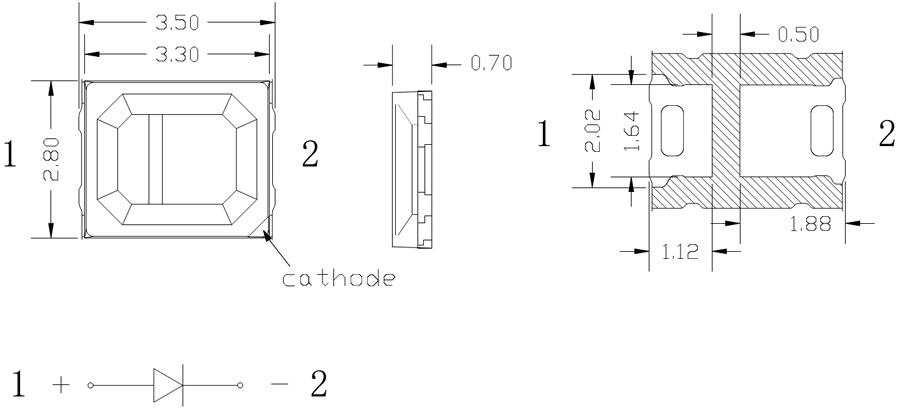

Package Dimensions

Notes:

1. All dimensions are in mm 。

2. Tolerance is ±0.2mm unless otherwise noted. ,±0.2

Absolute Maximum Ratings (TA=25℃)

|

Parameter

|

Symbol

|

Rating

|

Unit

|

|

Power Dissipation

|

PD

|

0.2

|

W

|

|

Forward Current

|

IF

|

60

|

mA

|

|

Peak Forward Current

|

IFP

|

100

|

mA

|

|

Operation Temperature Range

|

Topr

|

-35 to +60

|

℃

|

|

Storage Temperature Range

|

Tstg

|

-40 to +70

|

℃

|

|

ESD Sensitivity (HBM)

|

--

|

2000

|

V

|

|

Soldering Temperature

|

300±20℃/3~5sec

|

NOTE:﹡Pulse width≤0.1msec Duty Ratio≤1/10

Electrical-Optical Characteristics (TA=25℃)

|

Parameter

|

Test Condition

|

Symbol

|

Min

|

Typ

|

Max

|

Unit

|

|

Forward Voltage

|

IF=60mA

|

VF

|

---

|

3.0

|

---

|

V

|

|

Reverse Current

|

VR=-5V

|

IR

|

---

|

---

|

5

|

μA

|

|

View Angle

|

IF=60mA

|

2θ1/2

|

---

|

120

|

---

|

deg.

|

|

Luminous flux

|

IF=60mA

|

ΦV

|

26

|

---

|

28

|

lm

|

|

Color Coordinates

|

IF=60mA

|

X

|

---

|

0.44

|

---

|

|

|

Y

|

---

|

0.40

|

---

|

|

|

Color Temperature

|

IF=60mA

|

CCT

|

---

|

3000

|

---

|

K

|

|

Color Rendering index

|

IF=60mA

|

Ra

|

80

|

---

|

---

|

---

|

|

Color tolerance

|

IF=60mA

|

SDCM

|

---

|

---

|

6

|

---

|

Note: the test tolerance

VF : ±0.05V CCT : ±5% XY : ±0.005 ΦV : ±10%

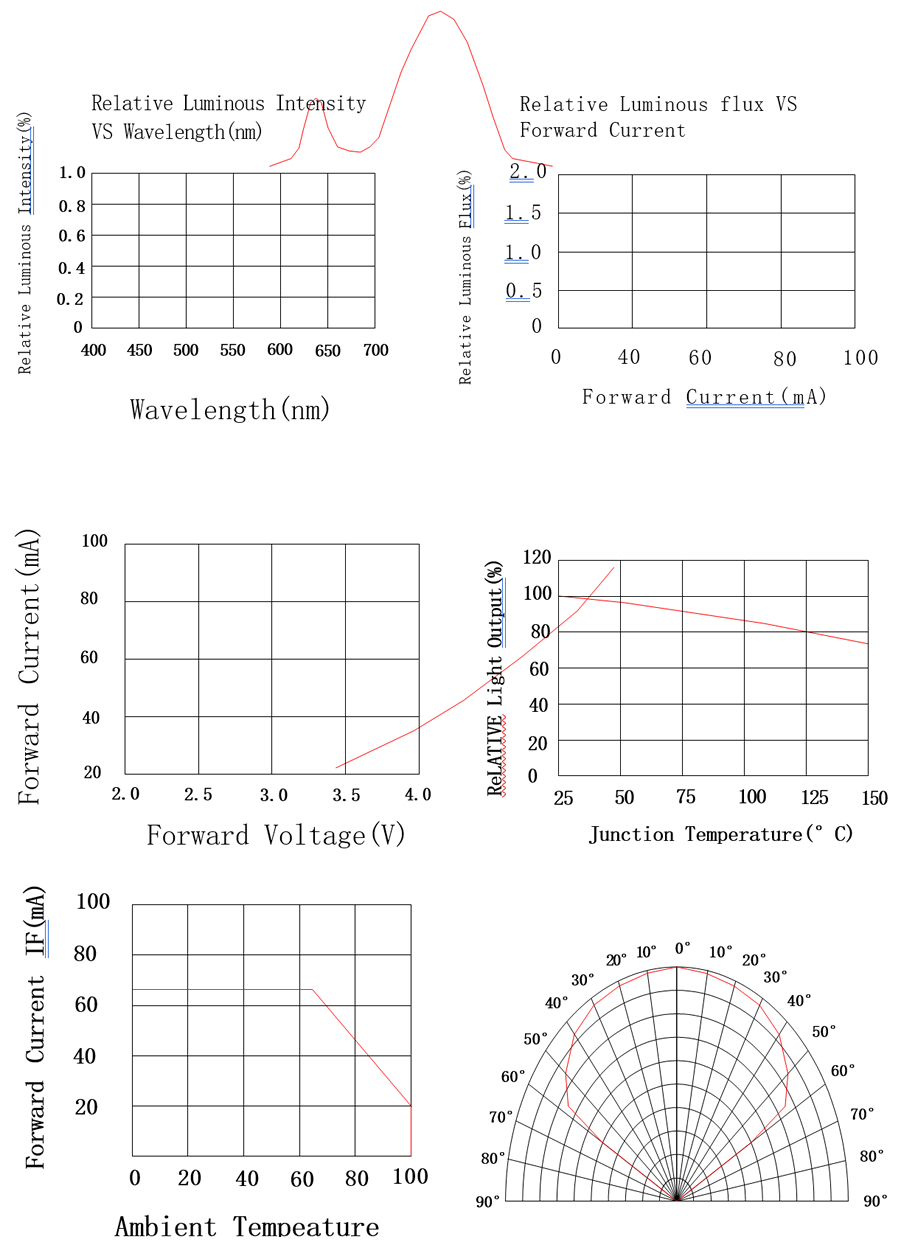

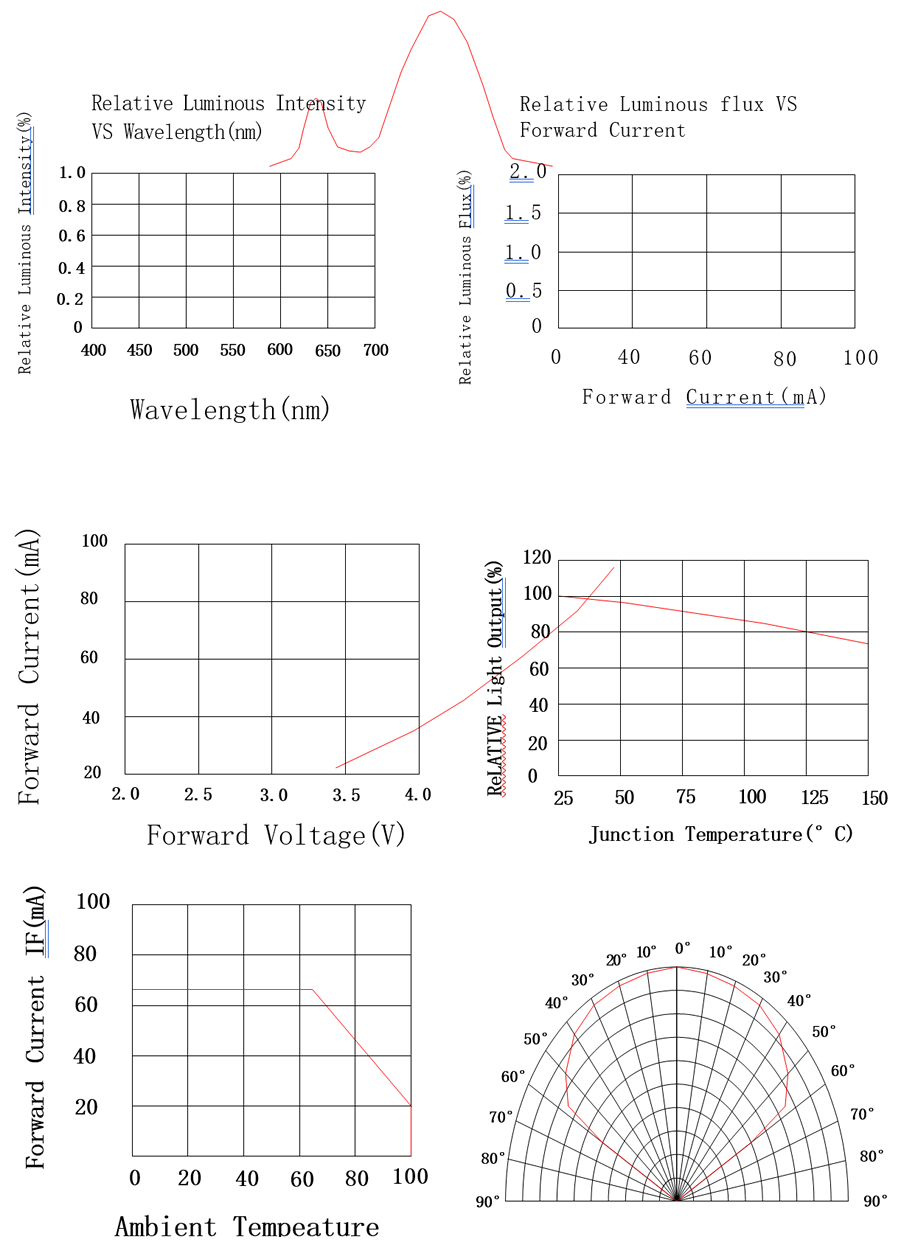

Typical Electrical/Optical Characteristic Curves(If=60mA;TA=25℃)

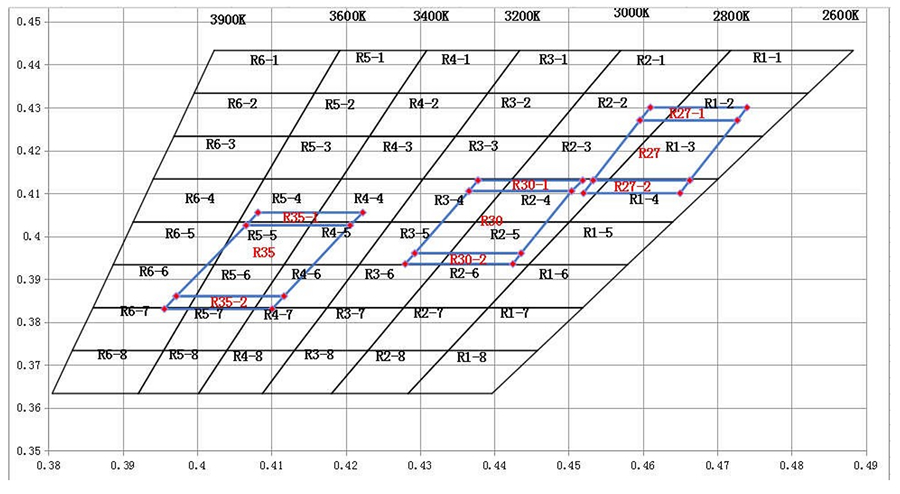

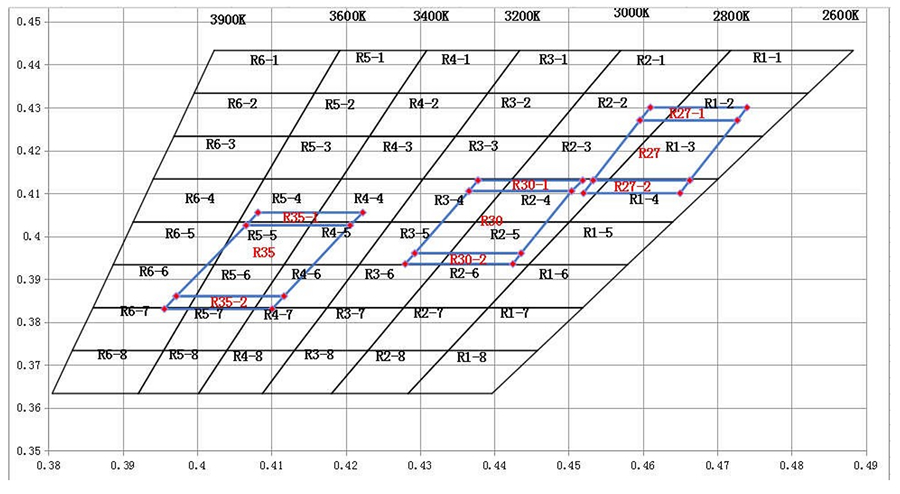

CIE Chromaticity Diagram:(If=60mA;TA=25℃)

CIE

Reliability

1. Test Items And Results

|

Item

|

Test conditions

|

Note

|

Number of Damaged

|

|

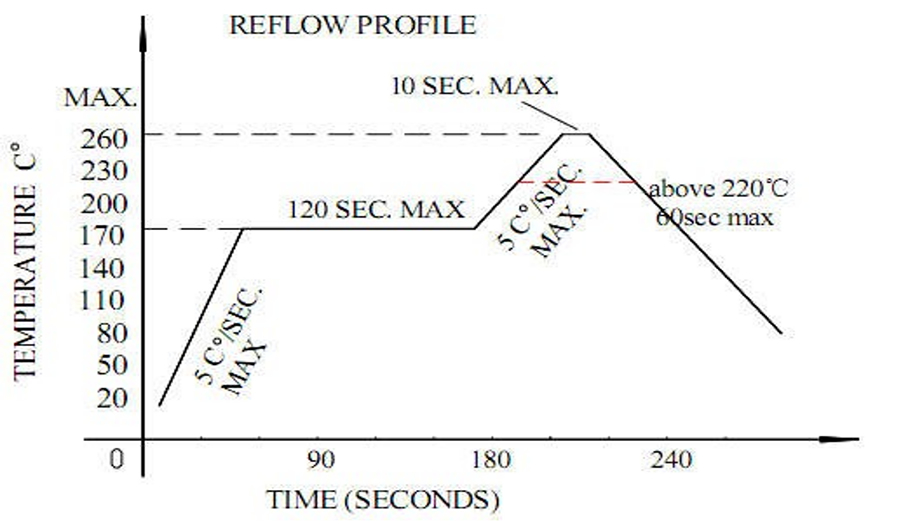

Reflow

|

Temp:260℃max T=10 sec

|

2 time

|

0/30

|

|

Thermal Shock

|

-40~100℃ 30min, 10s, 30min

|

100cycles

|

0/30

|

|

High Temperature High Humidity Storage

|

Ta=60℃,RH=90%

|

300hrs

|

0/30

|

|

Steady State Operating life

|

Ta=25℃,IF=60mA

|

1000hrs

|

0/30

|

|

Steady State Operating life of High Humidity Heat

|

Ta=60℃ RH=90%,IF=60mA

|

1000hrs

|

0/30

|

|

High Temperature Storage

|

Ta=100℃

|

1000HRS

|

0/30

|

|

Low Temperature Storage

|

Ta-=-40℃

|

1000HRS

|

0/30

|

2.Criteria for Judging The Damage

|

Item

|

Symbol

|

Test Conditions

|

Criteria for Judgment

|

|

Min.

|

Max.

|

|

Forward Voltage

|

VF

|

IF =60 mA

|

---

|

Initial Data ×1.1

|

|

Luminous Intensity

|

IV

|

IF =60 mA

|

Initial Data × 0.9

|

---

|

|

Reverse Current

|

IR

|

VR = 5V

|

---

|

Initial Data x2.0

|

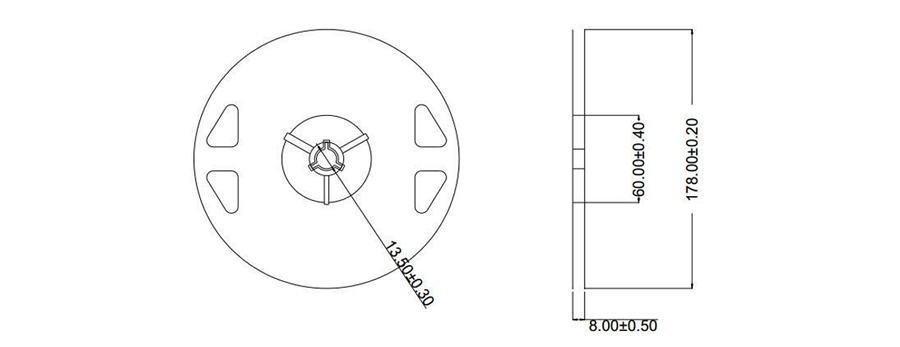

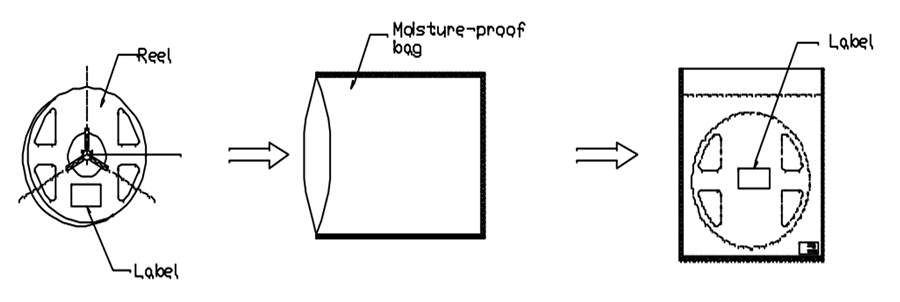

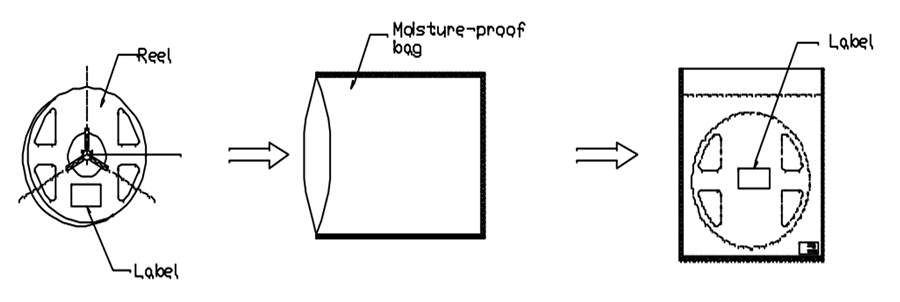

Packaging smd led 2835

Dimensions of Tape

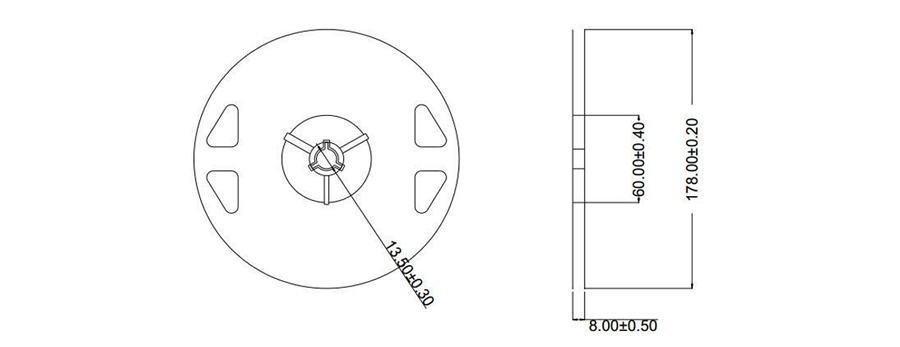

Dimensions of Reel

Packaging specifications

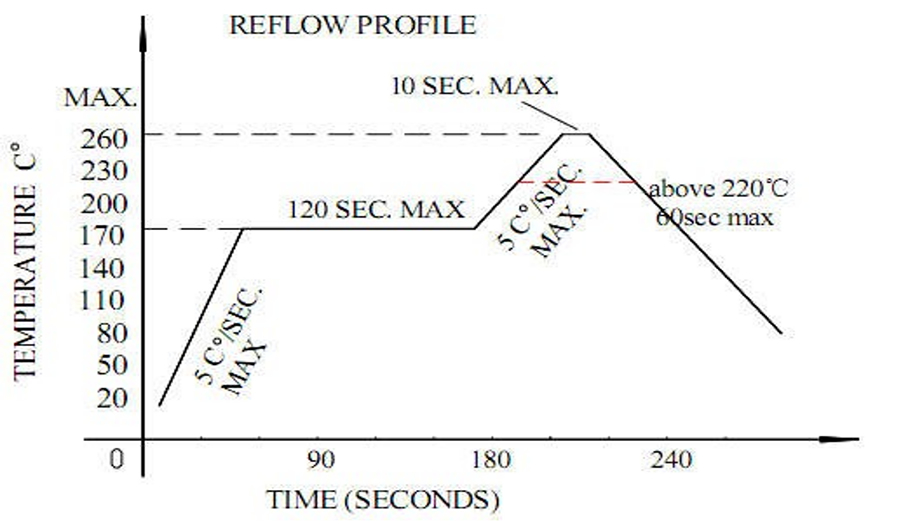

SMT Reflow Soldering Instructions SMT

1. Reflow soldering should not be done more than two times

2. When soldering, do not put stress on the 2835 smd LEDs during heating

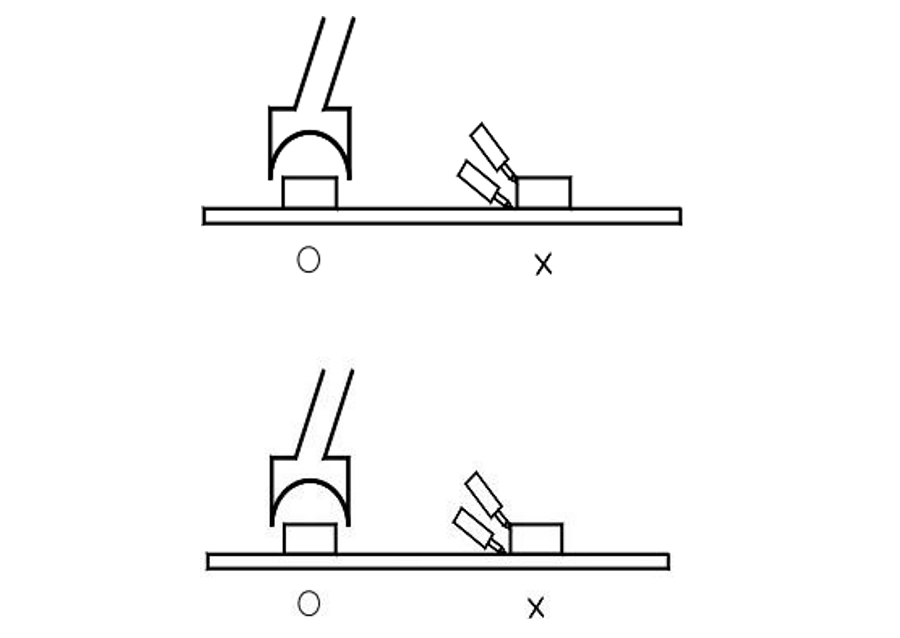

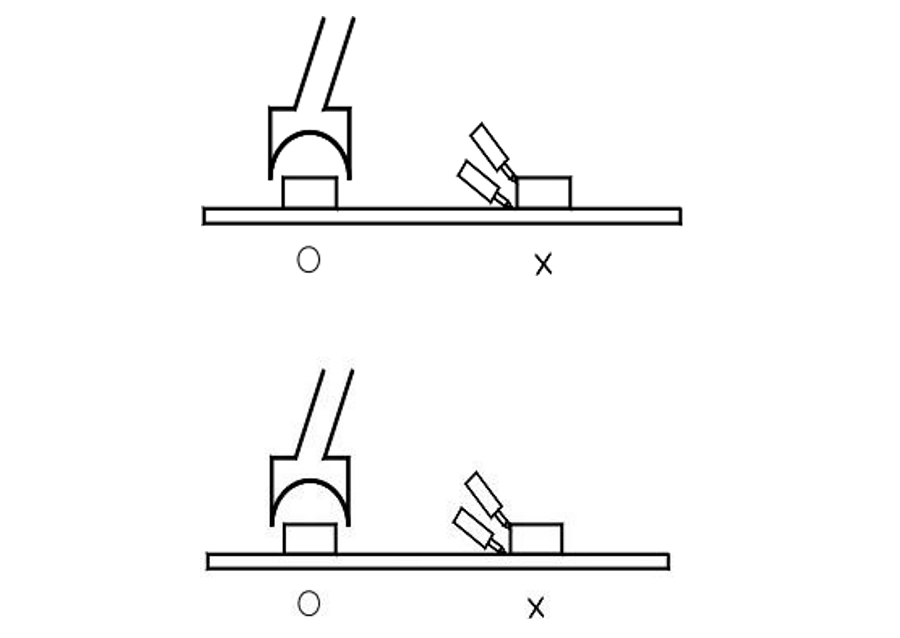

Soldering iron

1. When hand soldering, keep the temperature of the iron under 300℃,and at that temperature keep the time under 3 sec.

2. The hand soldering should be done only one time,

Rework

1. Customer must finish rework within 3 sec under 300℃

2. The head of iron can not touch the resin

3. Twin-head type is preferred.

CAUTIONS

Static Electricity

• Static electricity or surge voltage damages the 2835 SMD LED. It is recommended that a wrist band or an anti-electrostatic glove be used when handing the 2835 smd LED.

• A tip soldering iron is requested to be grounded, An ionizer should also be installed where risk of static.

• All devices, equipment and machinery must be properly grounded, It is recommended that measures be taken against surge voltage to the equipment that mounts the 2835 smd LED.

Heat generation

• When the 2835 smd LED are illuminating, operating current should be decided after be considering the ambient maximum temperature.

• Please consider the heat generation of the 2835 smd LED when it is designed the PCB.

• The 2835 smd LED must be mounted on metal core PCB or heat sink or applied thermal pad.

Handing LED

It recommends the following at all times when handing smd LED 2835 or assemblies containing the these LEDs:

• When handing the LED with tools like Tweezer or Nipper, do not apply Mechanical Forces directly on 2835 LED's Surface.

• Do not touch with hand LED Lens surface directly. It may contaminate the Lens surface and affect on optical characteristics.

• 2835 SMD LED should be handled from side because LED's molding material may be damaged with scratching on surface, piercing molding material and broking wire.