3030 smd led Features

Forward Voltage 3V 6V 9V Available

Forward Current 350mA 150mA 100mA

Color Rendering Index: RA80, RA90, RA93, RA95+, RA98

High Light Efficacy: 200LM/W+

CCT Range: 1600-1800K, 1800-2000K, 2000-2200K, 2200-2400K, 3000-10000K

Light Color: Red, Green, Blue, Yellow, UV, IR...

Full Spectrum 380-850nm

3030 smd led Specifications

|

Product Name

|

Light Color

|

CCT/Wavelength

|

Voltage

|

Current

|

Lumen

|

Remark

|

|

3030 LED

|

Gold Yellow

|

1800-2000K

|

3/6/9V

|

350/175/100mA

|

120-150LM

|

CRI80,90

|

|

3030 LED

|

White

|

3000-10000K

|

3/6/9V

|

350/175/100mA

|

120-180LM

|

CRI80,90,96+

|

|

3030 UV LED

|

UV

|

365-370nm

|

3/6/9V

|

350/175/100mA

|

/

|

Epileds Chip

|

|

3030 UV LED

|

UV

|

390-400nm

|

3/6/9V

|

350/175/100mA

|

/

|

Epileds Chip

|

|

3030 BLUE LED

|

Blue

|

440-470nm

|

3/6/9V

|

350/175/100mA

|

12-20LM

|

Epileds Chip

|

|

3030 Green LED

|

Green

|

520-530nm

|

3/6/9V

|

350/175/100mA

|

70-100LM

|

Epileds Chip

|

|

3030 Amber LED

|

Yellow/Amber

|

590-610nm

|

2/4/6V

|

350/175/100mA

|

20-25LM

|

Epileds Chip

|

|

3030 Red LED

|

Red

|

620-630nm

|

2/4/6V

|

350/175/100mA

|

30-35LM

|

Epileds Chip

|

|

3030 Far Red

|

Far Red

|

660-665nm

|

2/4/6V

|

350/175/100mA

|

12-15LM

|

Epileds Chip

|

|

3030 IR LED

|

IR

|

730-750nm

|

2/4/6V

|

350/175/100mA

|

/

|

Epileds Chip

|

|

3030 IR LED

|

IR

|

850nm

|

2/4/6V

|

350/175/100mA

|

/

|

Epileds Chip

|

|

3030 PC Blue

|

Phosphor Blue

|

450-470nm

|

3/6/9V

|

350/175/100mA

|

15-30LM

|

Customized WD, WP

|

|

3030 PC Green

|

Phosphor Green

|

510-530nm

|

3/6/9V

|

350/175/100mA

|

140-200LM

|

Customized WD, WP

|

|

3030 PC Color

|

Phosphor Amber/Red

|

600-630nm

|

3/6/9V

|

350/175/100mA

|

50-60LM

|

Customized WD, WP

|

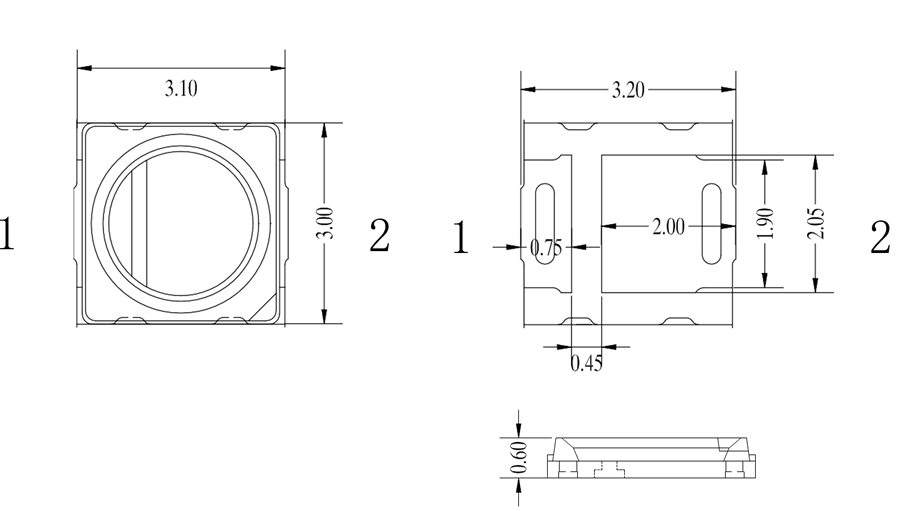

Notes:

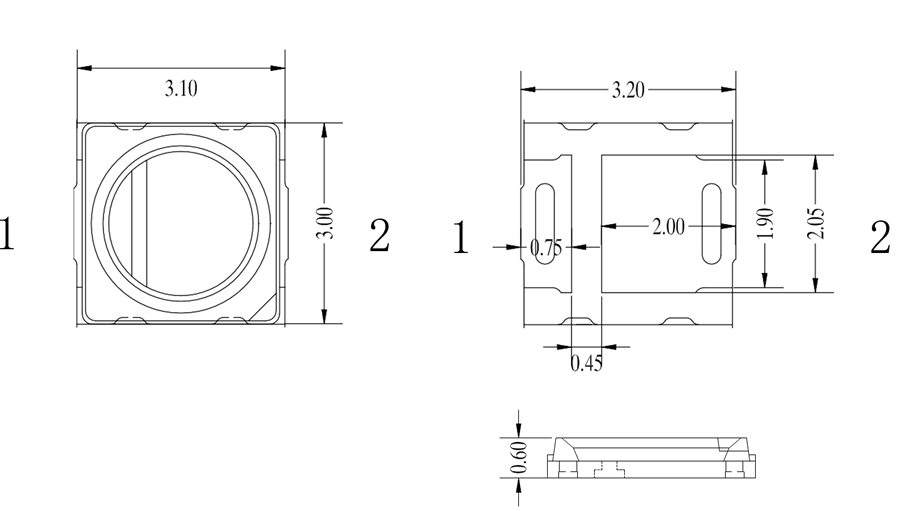

1. All dimensions are in mm 。

2. Tolerance is ±0.2mm unless otherwise noted. ,±0.2 。

Absolute Maximum Ratings (TA=25℃)

|

Parameter

|

Symbol

|

Rating

|

Unit

|

|

Power Dissipation

|

PD

|

1

|

W

|

|

Forward Current

|

IF

|

150

|

mA

|

|

Peak Forward Current

|

IFP

|

200

|

mA

|

|

Operation Temperature Range

|

Topr

|

-35 to +60

|

℃

|

|

Storage Temperature Range

|

Tstg

|

-40 to +70

|

℃

|

|

ESD Sensitivity (HBM)

|

--

|

2000

|

V

|

|

Soldering Temperature

|

300±20℃/3~5sec

|

NOTE:

Pulse width ≤0.1msec

Duty Ratio ≤1/10

Electrical-Optical Characteristics (TA=25℃)

|

Parameter

|

Test Condition

|

Symbol

|

Min

|

Typ

|

Max

|

Unit

|

|

Forward Voltage

|

IF=150mA

|

VF

|

5.8

|

---

|

6.5

|

V

|

|

Reverse Current

|

VR=-5V

|

IR

|

---

|

---

|

5

|

μA

|

|

View Angle

|

IF=150mA

|

2θ1/2

|

---

|

120

|

---

|

deg.

|

|

Luminous flux

|

IF=150mA

|

ΦV

|

140

|

---

|

150

|

lm

|

|

Color Coordinates

|

IF=150mA

|

X

|

---

|

0.32

|

---

|

|

|

Y

|

---

|

0.33

|

---

|

|

|

Color Temperature

|

IF=150mA

|

CCT

|

---

|

6000

|

---

|

K

|

|

Color Rendering index

|

IF=150mA

|

Ra

|

80

|

---

|

---

|

---

|

Note: the test tolerance

VF : ±0.05V CCT : ±5% XY : ±0.005 ΦV : ±10%

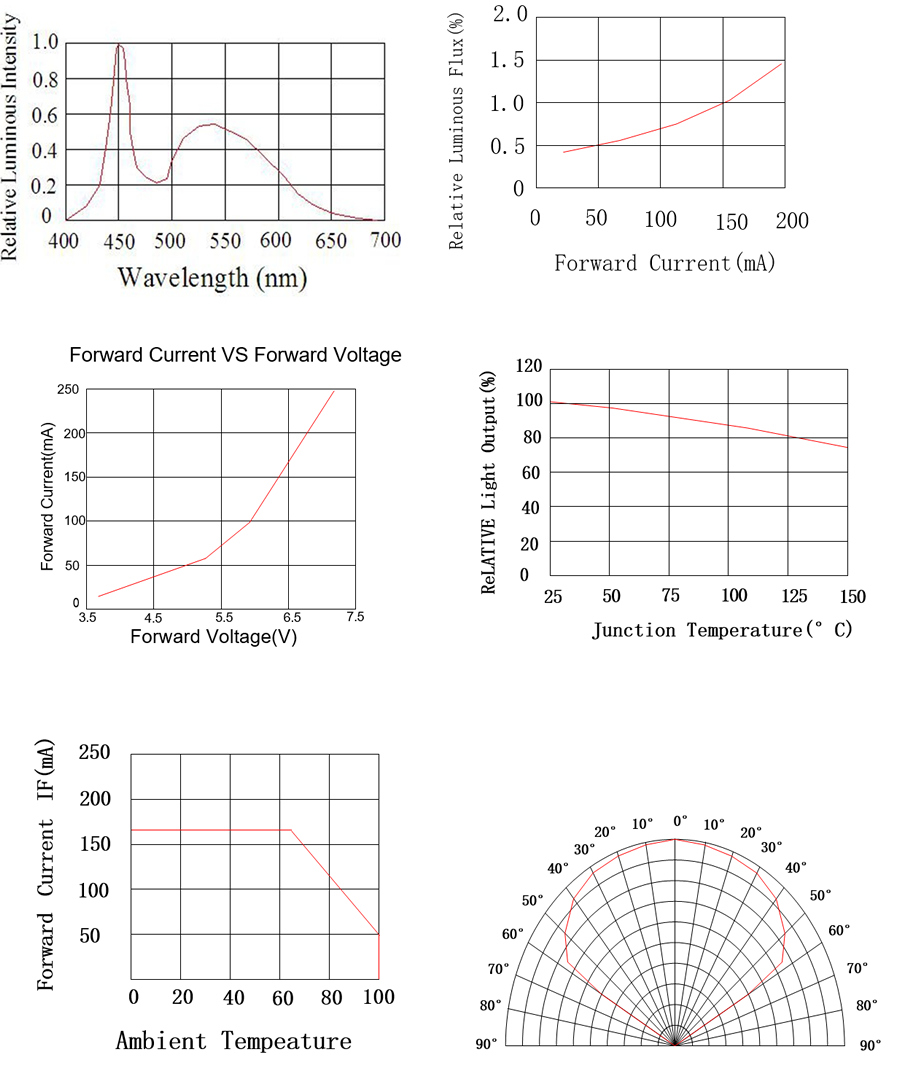

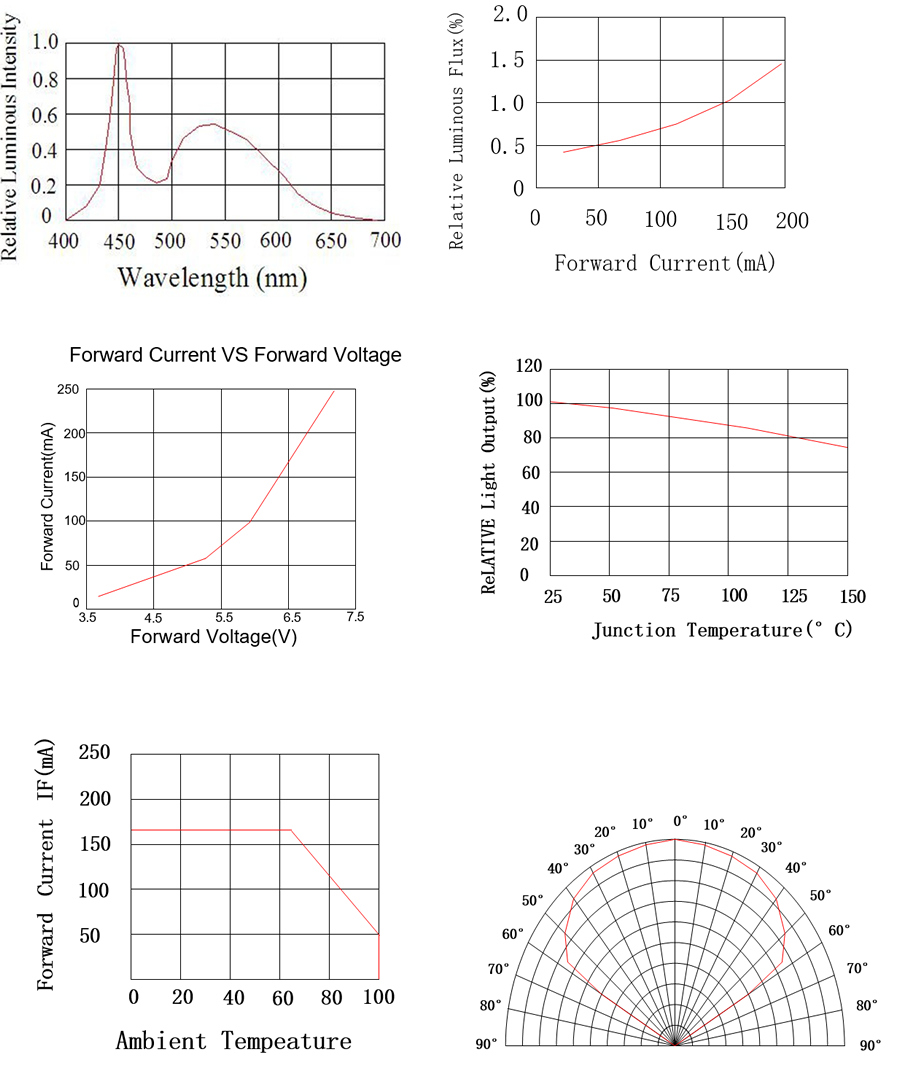

Typical Electrical/Optical Characteristic Curves(If=150mA;TA=25℃)

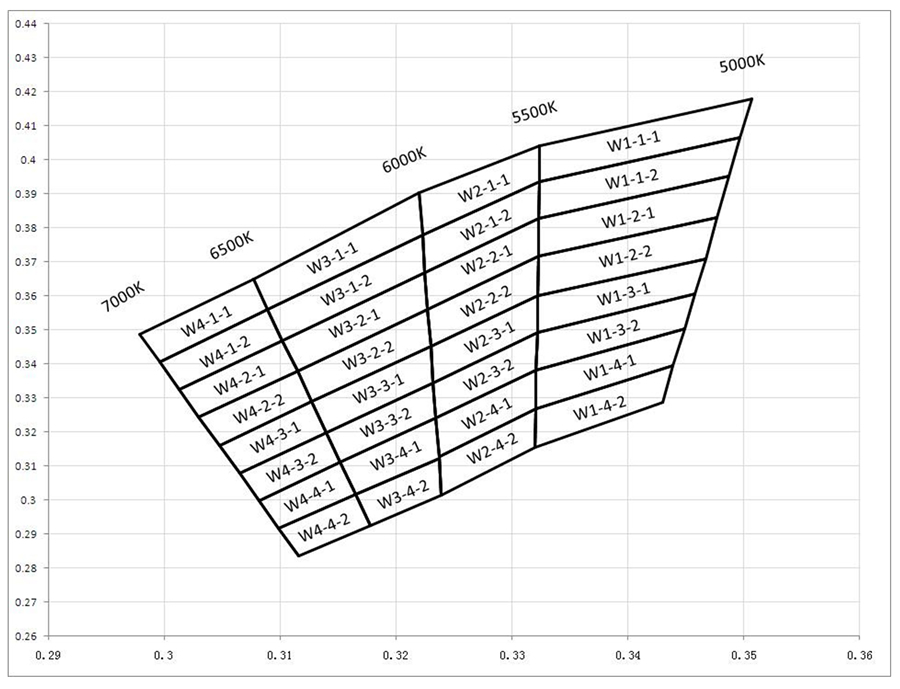

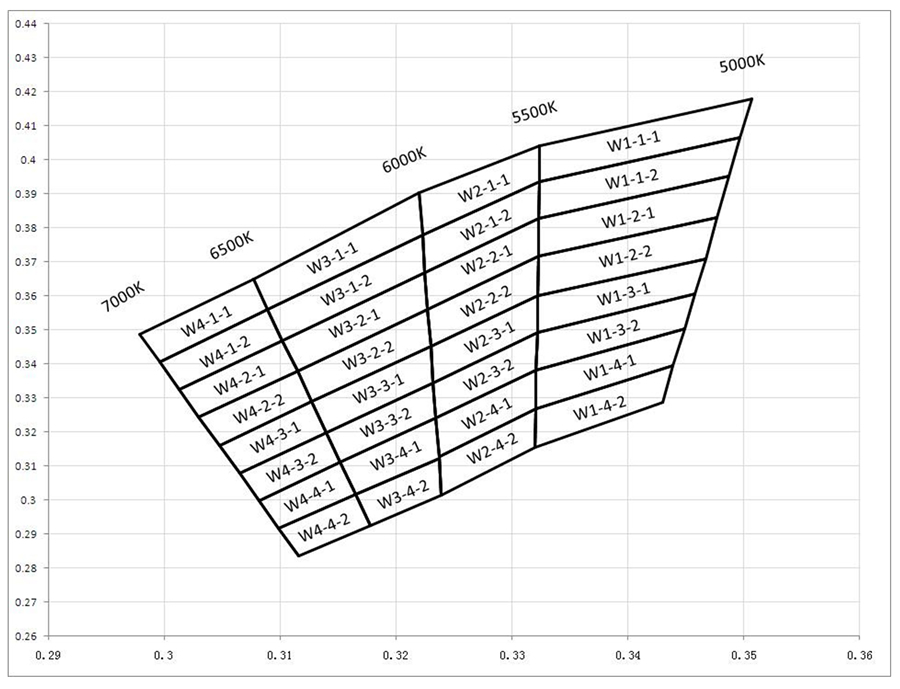

CIE Chromaticity Diagram:(If=150mA;TA=25℃)CIE

Reliability

1. Test Items And Results

|

Item

|

Test conditions

|

Note

|

Number of Damaged

|

|

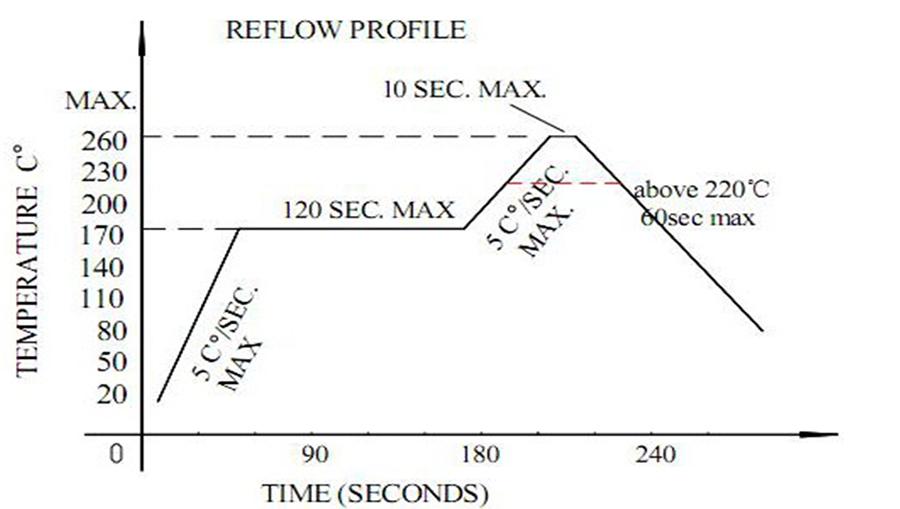

Reflow

|

Temp:260℃max T=10 sec

|

2 time

|

0/30

|

|

Thermal Shock

|

-40~100℃ 30min, 10s, 30min

|

100cycles

|

0/30

|

|

High Temperature High Humidity Storage

|

Ta=60℃,RH=90%

|

300hrs

|

0/30

|

|

Steady State Operating life

|

Ta=25℃,IF=150mA

|

1000hrs

|

0/30

|

|

Steady State Operating life of High Humidity Heat

|

Ta=60℃ RH=90%,IF=150mA

|

1000hrs

|

0/30

|

|

High Temperature Storage

|

Ta=100℃

|

1000HRS

|

0/30

|

|

Low Temperature Storage

|

Ta-=-40℃

|

1000HRS

|

0/30

|

2. Criteria for Judging The Damage

|

Item

|

Symbol

|

Test Conditions

|

Criteria for Judgment

|

|

Min.

|

Max.

|

|

Forward Voltage

|

VF

|

IF =150 mA

|

---

|

Initial Data ×1.1

|

|

Luminous Intensity

|

IV

|

IF =150 mA

|

Initial Data × 0.9

|

---

|

|

Reverse Current

|

IR

|

VR = 5V

|

---

|

Initial Data x2.0

|

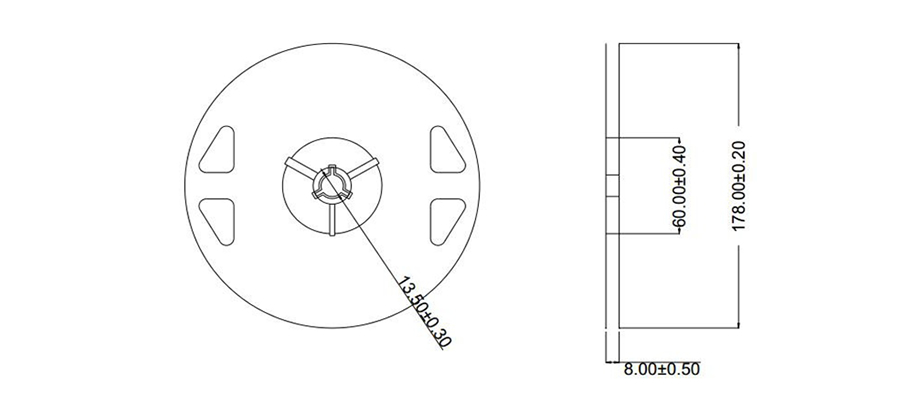

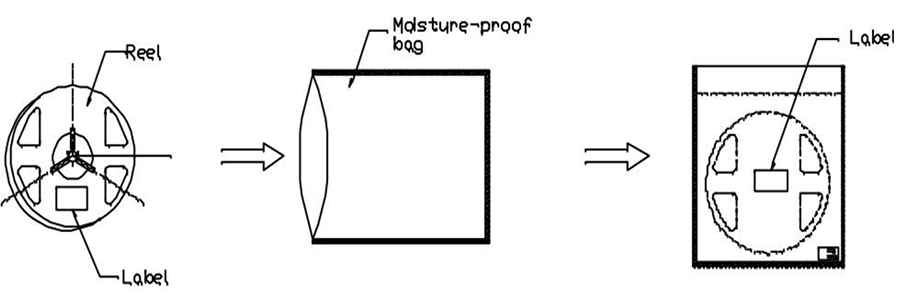

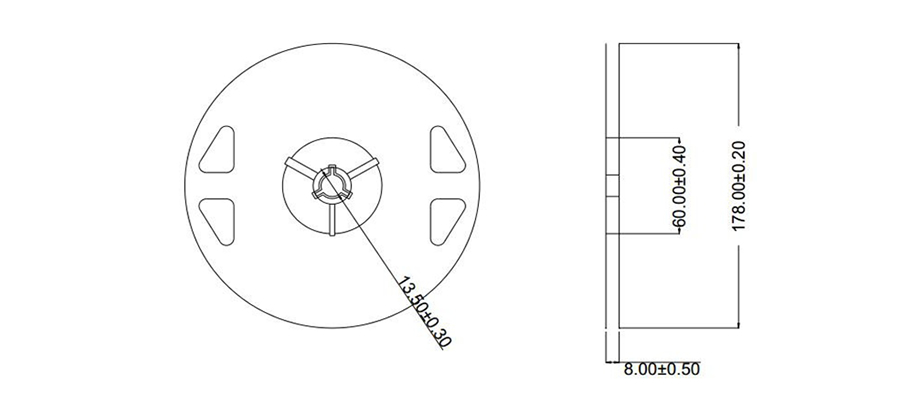

Packaging Specifications

Dimensions of Tape

Dimensions of Reel

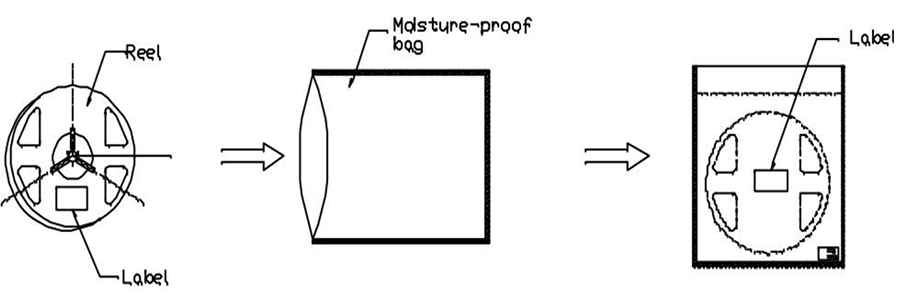

Packaging specifications

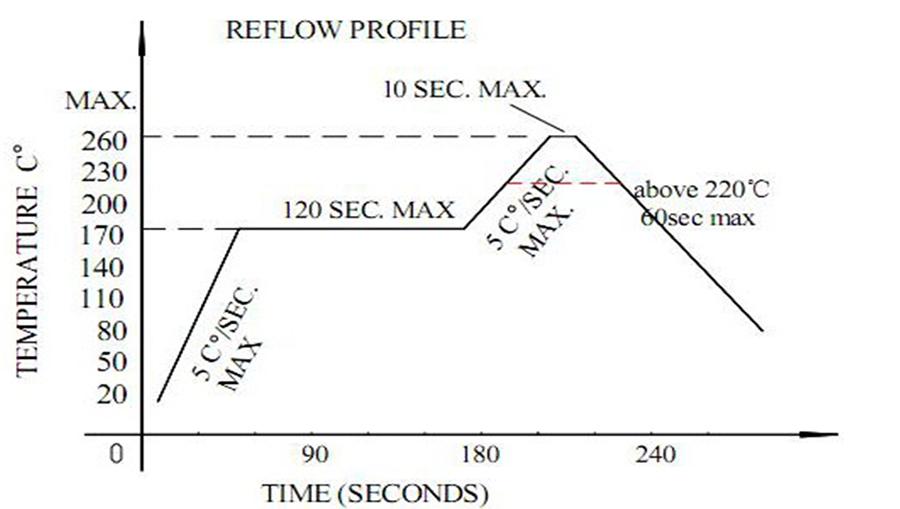

SMT Reflow Soldering Instructions SMT

1. Reflow soldering should not be done more than two times

2. When soldering, do not put stress on the 3030 LEDs during heating

Soldering iron

1. When hand soldering, keep the temperature of the iron under 300℃,and at that temperature keep the time under 3 sec.

2. The hand soldering should be done only one time,

Rework

1. Customer must finish rework within 3 sec under 300℃

2. The head of iron can not touch the resi

3. Twin-head type is preferred.

CAUTIONS

The encapsulated material of the 3030 smd LED is silicone .Therefore the 3030 LED have a soft surface on the top of package. The pressure to the top surface will be influence to the reliability of the LEDs. Precautions should be taken to avoid the strong pressure on the encapsulated part. So when using the picking the picking up nozzle, the pressure on the silicone resin should be proper.