Application

1W G30/G38/G42 )

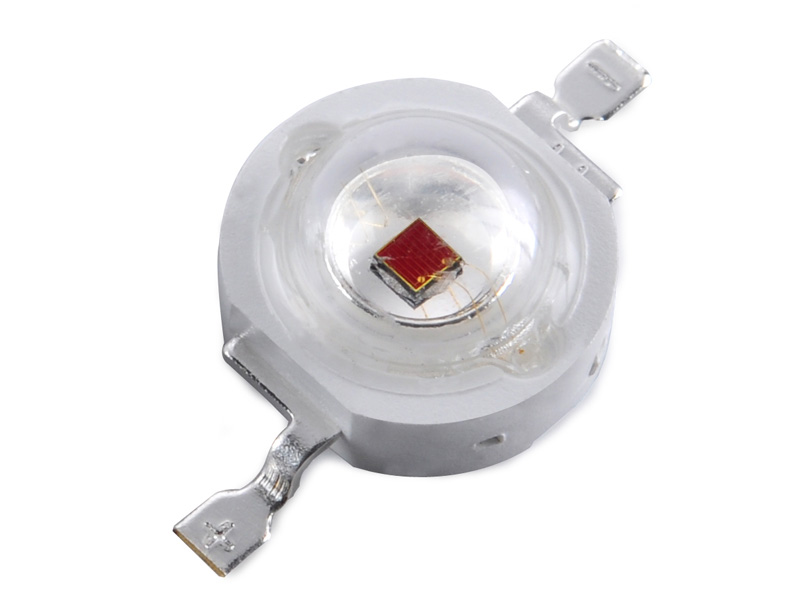

This specification applies only to models of high power led(1W G30/G38/G42 Red)LED .

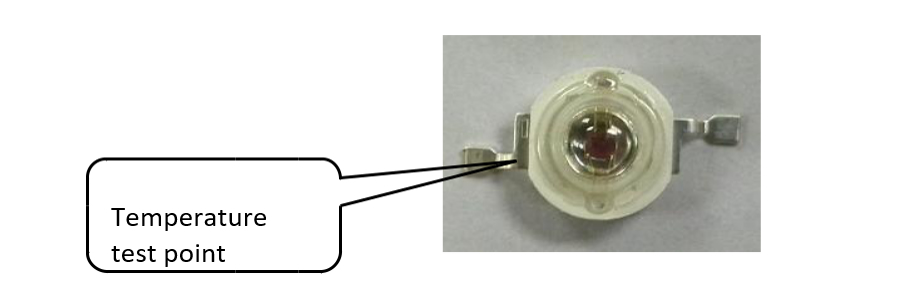

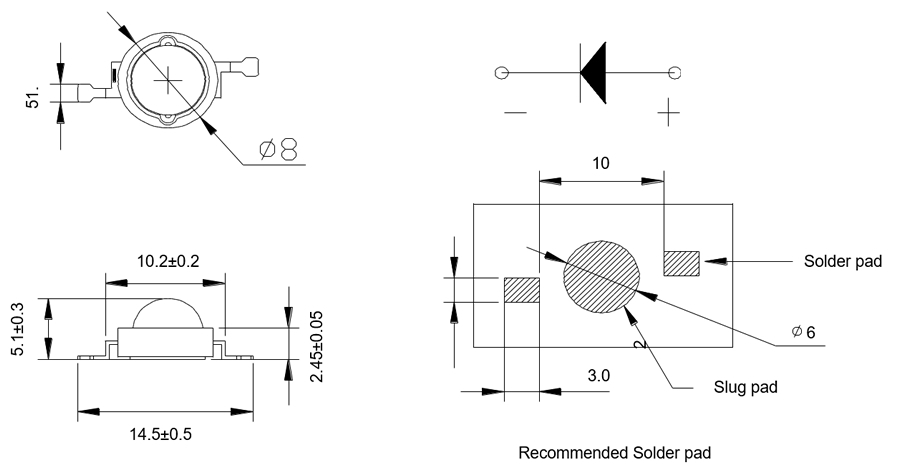

1.1 Feature

14.5mm×8.0mm×5.1mm

Package Dimensions:14.5mm×8.0mm×5.1mm

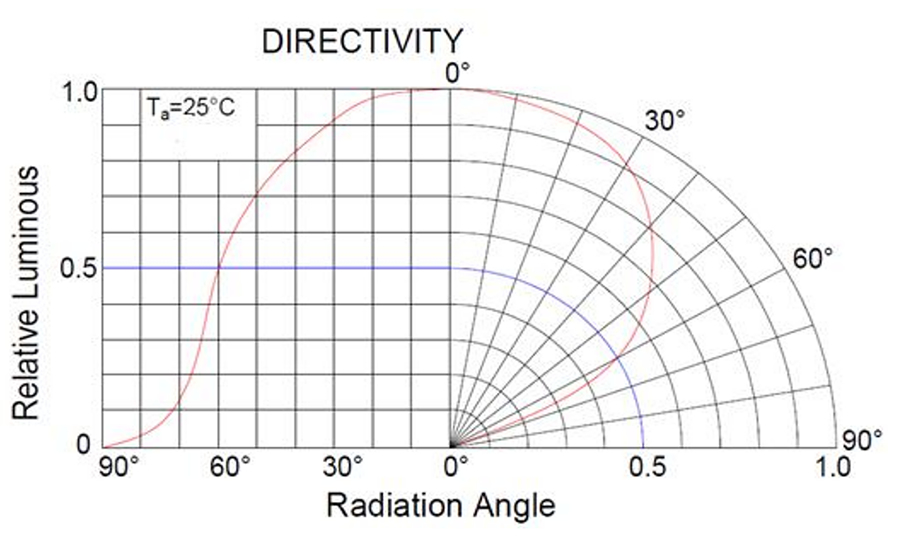

Beam Angle:120°

RoHS Approved

Normal PC lens is suitable for manual welding

High-temperature lens is suitable for reflow soldering

2:Main application: Lighting

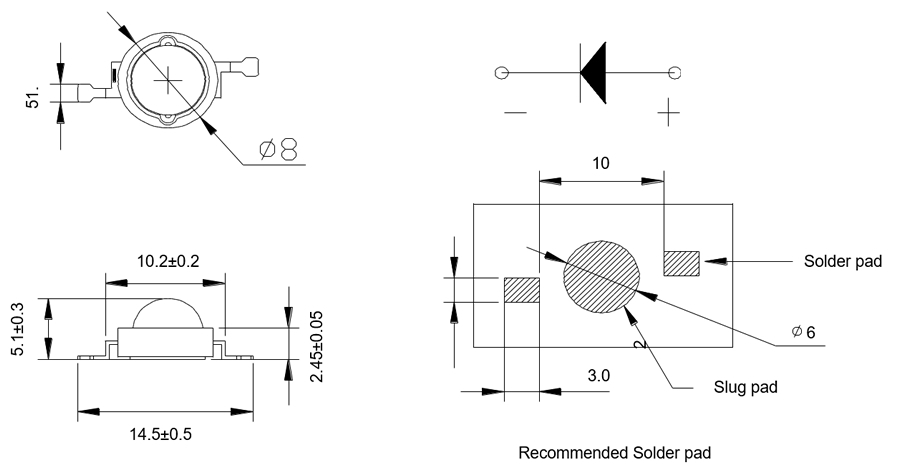

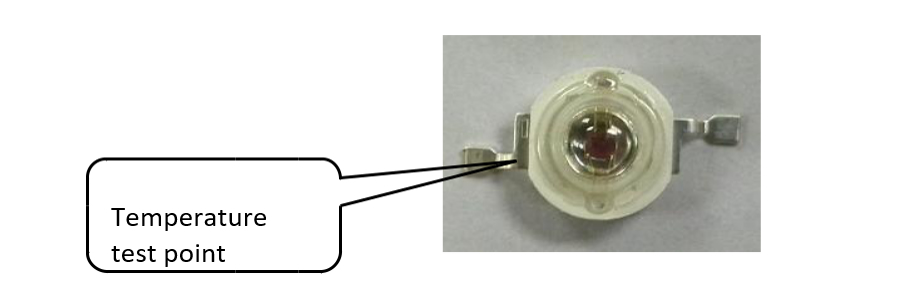

Demension and Circuit

Unit:mm Tolerance:+-0.2mm Conduction support material:copper

3.Characteristics:

3-1. Absolute Maximum Ratings

|

Item

|

Symbol

|

Value

|

Unit

|

|

*1

|

P

|

1.0

|

W

|

|

Max power

|

|

|

|

|

|

*1

|

IF

|

350

|

mA

|

|

DC Forward Current

|

|

|

|

|

|

*2

|

VR

|

-5

|

V

|

|

Reverse Current

|

|

|

|

|

|

|

Tj

|

115

|

℃

|

|

Junction Temperature

|

|

|

|

|

|

*3

|

TOPR

|

-30~+60

|

℃

|

|

Operating temperature

|

|

|

|

|

|

|

TSTG

|

-35~+100

|

℃

|

|

Storage Temperature

|

|

|

ESD

|

2000

|

V

|

|

Electrostatic Limit

|

|

|

|

|

|

|

|

350℃/3-5S

|

|

|

Soldering Temperature

|

|

|

Additional Remarks

1.Max power and positive current mean the maximum setting value of the bottom terperature of led light source by using the appropriate heat sink.

2.Originally connection error and off-limits voltage may damage LED chip.

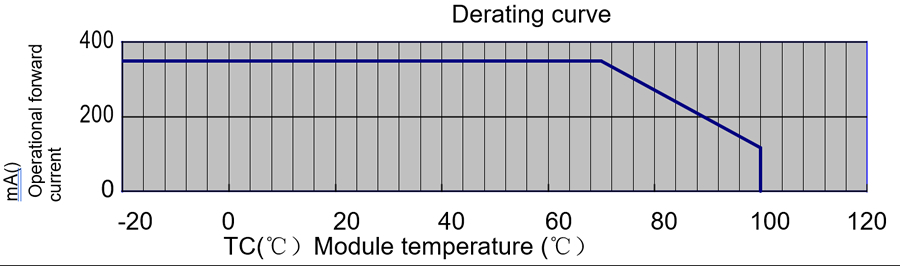

3.Different temperatures, corresponding temperature test point on the next, said 1W LED light should operate follow derating curve on the text.

3-2. Derating curve:

Note : In order to keep the temperature below the rated , you should make sure that the radiator has enough heat dissipation performance.

3-3.:Optical Characteristics

|

Parameter

|

Symbol

|

Condition

|

color

|

Min.

|

Typ.

|

Max.

|

LM/W

|

Unit

|

|

|

|

|

R

|

2.0

|

2.25

|

2.4

|

|

|

|

VF

|

IF=350mA

|

G

|

|

|

|

/

|

V

|

|

|

|

|

|

|

|

|

|

B

|

|

|

|

|

|

|

|

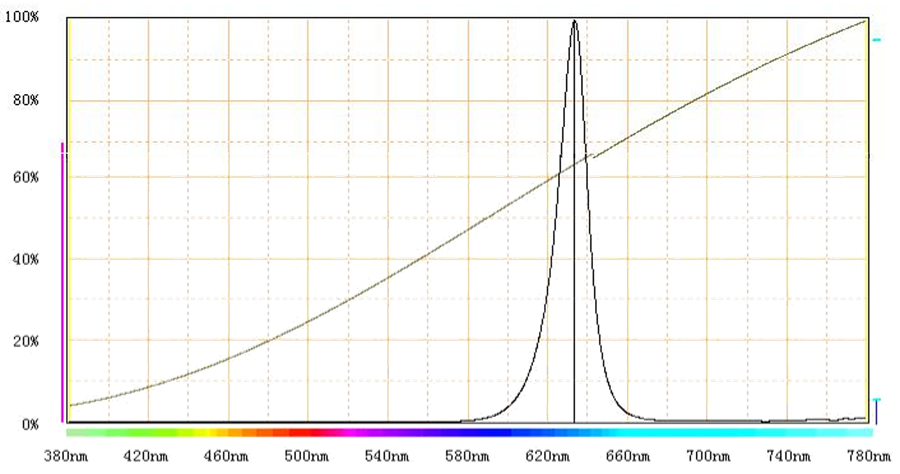

λd(R)

|

IF=350mA

|

R

|

620.0

|

622.5

|

625.0

|

/

|

nm

|

|

Domi

|

λd(G)

|

G

|

|

|

|

|

Wavelength

|

λd(B)

|

|

B

|

|

|

|

|

|

|

|

|

G30

|

R

|

30

|

35

|

40

|

>30

|

|

|

|

|

G38

|

R

|

40

|

45

|

50

|

>40

|

|

|

|

|

G42

|

R

|

45

|

50

|

55

|

>45

|

|

|

|

|

G35

|

G

|

|

|

|

|

|

|

Luminous

|

Φv

|

G40

|

G

|

|

|

|

-

|

Lm(LM/W)

|

|

flux

|

|

G45

|

G

|

|

|

|

-

|

|

|

|

|

G35

|

B

|

|

|

|

|

|

|

|

|

G40

|

B

|

|

|

|

-

|

|

|

|

|

G45

|

B

|

|

|

|

-

|

|

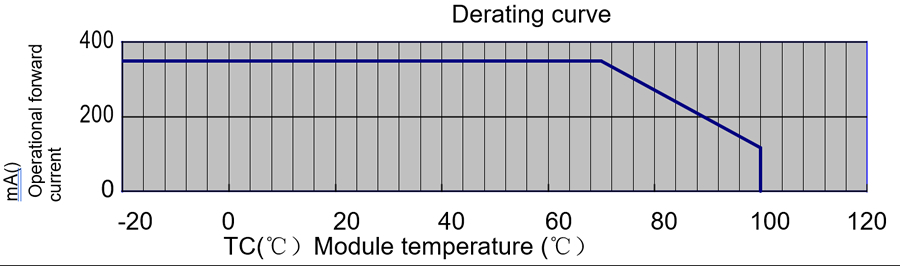

3-4.(TYP) Characteristics Diagram(TYP)

3-4.1: Relative Spectral Distribution Graph:

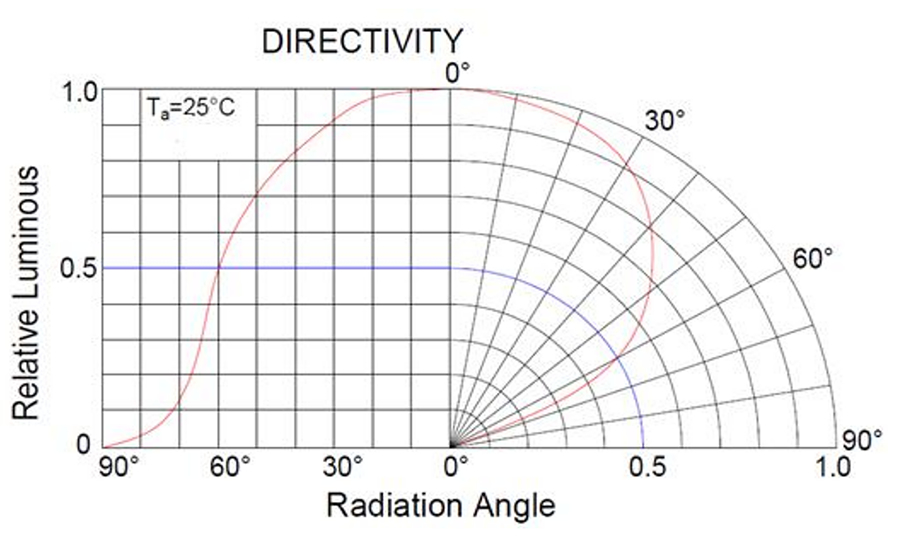

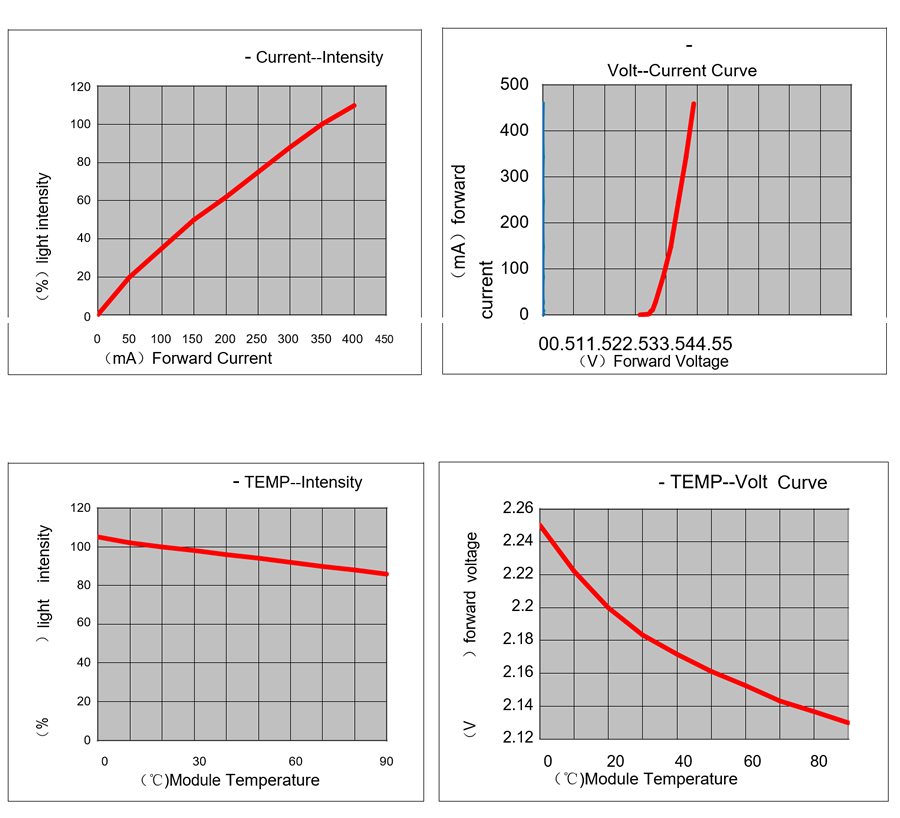

3-4.2 Luminous Flux Distribution

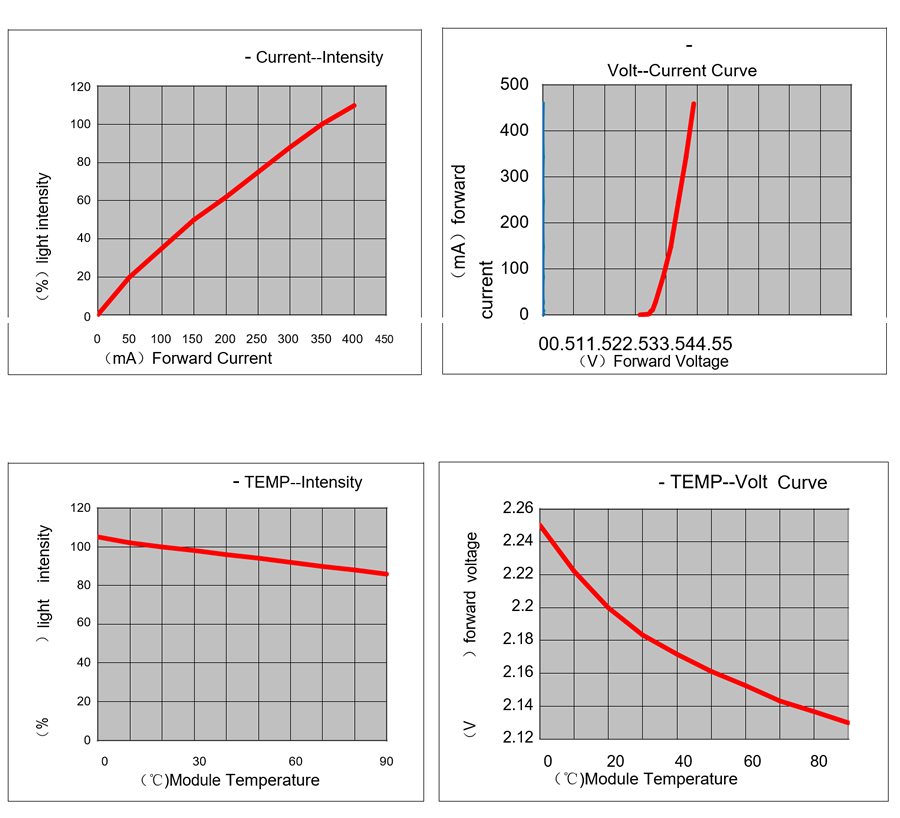

3-4.3Other optical Curves

Reliability

Reliability will meet the following items 4-1. Testing items and testing conditions

|

Serial No.

|

Test Item

|

Test condition

|

Sample

Quantity

|

Failure

Quantity

|

|

1

|

Thermal shock

|

|

22

|

0

|

|

2

|

HighTemperature

|

+85℃,1000h

|

22

|

0

|

|

3

|

Low Temperature

|

-40℃,1000h

|

22

|

0

|

|

4

|

Humidity

Heat Storage

|

T=+85℃,RH>=85%,1000h

|

22

|

0

|

|

5

|

High-temperature

|

T=+85℃, IF=350mA 1000h

|

22

|

0

|

|

6

|

Low temperature

|

T=-40℃, IF=350mA 1000h

|

22

|

0

|

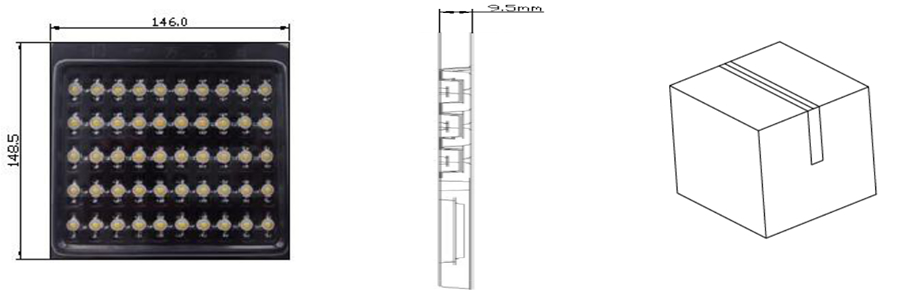

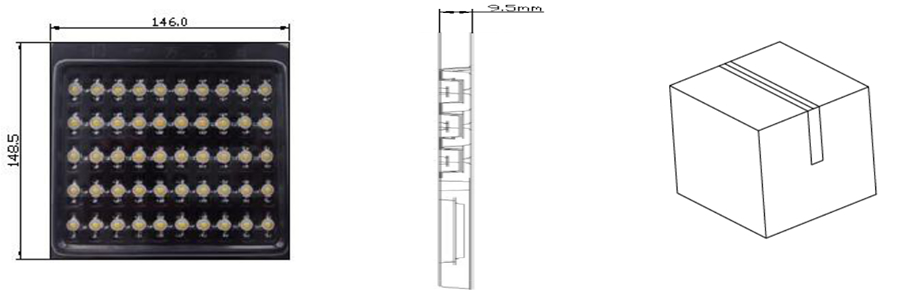

5.2 packaging

1-50PCS(146.0*148.5*9.5mm)

Red led 1W is packed in fluted plastic box with protection cover, preventing from ourside force.1-50pcs in one plastic box according to different requirements from customers(Outside demension of the plastice box is 146.0*148.5*9.5mm). Packed plastic box will be stored in carton and sealed,which is showed as the picture.

6. Caution

6.1 ::5~30℃,60%。(15):60°C±5°C,24H

6.1 Storage condition: Before opening: the temperature is 5 ~ 30 ℃, relative humidity less than 60%. (After opening the led light source should be used within 15 days.)For Unused Product,Please dehumidification vacuum sealed.Dehumidifying conditions: 60 °C ± 5 °C, 24H. Effective use of the product sealed for one year

6.2 Attention:

(1)PC(1.0-4.0MK/W),,350℃,3-5S;, PC

(1)thermal paster(Thermal Conductivity 1.0-4.0MK/W) should be used when connect the Red led 1W with normal PC lens to the radiator; two pins of leds shall be welded by thermostat soldering iron. Make sure that the welding temperature is under 350 ℃ and welding time in 3-5 Seconds; Assembly process to avoid external force on the colloid surface (such as pressure, friction or sharp metal nails, etc.), to avoid gold wire deformation or breakage and other abnormalities.Normal PC lens can't withstand high temperature , reflow soldering is not suitable for normal PC lens .

(2),200℃/5S High temperature LED lens is suitable for reflow soldering , and high-temperature lens can withstand 200℃ /5S , using low temperature solder paste ,in strict accordance with the reflow soldering welding operating standards .Specific operating refers to product use notes .

(3):TS 75℃,60℃。 (3)Red led 1W normal operating temperature: TS point (negative pad) is less than 75 degrees, The cooling body temperature less than 60degrees ,if exceeded our requirements for a given customer must make reliability assessment, resulting loss must be borne by the customer.

(4) Power Supply Select: Red led 1W is to be driven using a constant current source, and the output current of the power range meets the specifications of the book, for the use of a constant voltage source or other conditions, please do used result of risk assessment.

(5):LED SD protection is needed.

6.3 Other Instructions:

(1)LED( Cl2,H2S、NH3、SOx、NOx)

If you use the product in any of the following conditions, please make sure its normal performance and reliability.*Place where is moist or has dew、cream、salt air、 corrosive gases(C1, H2S, NH3, SO2, NOX, etc.)

(2)LED colloid surface dirt, use alcohol to clean.Can't use acetone caustic cleaning solvent to cleaning

7. Using Compatibility

7-1. The chemical composition of gas in lamps and surrounding environment of light source are essential to the life of the lamps, especially when you choose to use chemical composition, it is particularly important in lighting design. Before considering the use of any material, be sure to consult the product supplier or Red led 1W manufacturer. The more information obtained before using some material, the higher the performance of the lamp.

7-2. Many regular chemicals will release gaseous aromatic compounds (ie, aromatics), and even small amounts of these chemicals, the gases which they released also tend to cause Led discoloration or damage. The chemicals in test report Table 1 will cause damage of Red led 1W. Therefore, it is not recommended to use these chemicals in a solid state lighting system of Led or anywhere around the Red led 1W .

Common chemicals with LED compatibility issues

Chemicals removing hydrocarbon gas (such as toluene, benzene, xylene)

Methyl acetate or ethyl acetate (such as resurrection oil)

Cyanoacrylate (such as "glue")

Ethylene glycol ether and dipropylene glycol monomethyl ether (such as electronic equipment cleaner)

(pLIoBoND®)

Formaldehyde or butadiene (such as pLIoBoND® adhesive)

Chlorine, including detergent and sprays with bleach

7-3: The following sheet is the list of common basic materials and commercial products in electronics and electrical equipment. Some of those materials can cause serious damage or light color shift phenomenon. The results of a risk assessment related materials are as shown in the sheet:

5-4: The following sheet is the list of common basic materials and commercial products in electronics and electrical equipment. Some of those materials can cause serious damage or light color shift phenomenon. The results of a risk assessment related materials

|

Material Name

|

Type

|

Using

|

Outgassin

|

Prohibit

|

To Be Verified

|

|

Acetic acid

|

Acid

|

|

|

yes

|

|

|

Acetone

|

Manufacturing materials

|

|

yes

|

|

|

|

Acrylonitrile-butadiene-styrene (aBS)

|

Rubber / plastic sealant

|

yes

|

|

|

|

|

Ammonia

|

alkali

|

|

|

|

yes

|

|

Benzene

|

Solvent

|

|

|

|

yes

|

|

Butadiene rubber

|

Rubber / plastic sealant

|

|

|

|

yes

|

|

Butyl rubber

|

Rubber / plastic sealant

|

|

|

|

yes

|

|

polyvinyl chloride

|

Rubber / plastic sealant

|

|

|

|

yes

|

|

Chlorobutyl

|

Rubber / plastic sealant

|

|

|

|

yes

|

|

Chlorosulfonation rubber

|

Rubber / plastic sealant

|

|

|

|

yes

|

|

Cyanoacrylate

|

Sealants and adhesives

|

|

yes

|

yes

|

|

|

DCa SCC3

|

Paint / Glue

|

yes

|

yes

|

|

|

|

Dichloromethane

|

Solvent

|

|

|

|

yes

|

|

Propylene oxide

|

Rubber / plastic sealant

|

|

|

|

yes

|

|

Gasoline

|

Solvent

|

|

|

|

yes

|

|

graphite washer

|

Thermal grease

|

yes

|

yes

|

|

|

|

Halogenated hydrocarbons (including

|

|

|

yes

|

|

yes

|

|

HT902

|

Paint / Glue

|

yes

|

yes

|

|

|

|

Hydrochloric acid

|

Acid

|

|

|

|

yes

|

|

Isopropanol(Ipa)

|

cleanser

|

yes

|

yes

|

|

|

|

meK (methyl ethyl ketone)

|

Solvent

|

|

|

|

yes

|

|

mIBK (methyl isobutyl ketone)

|

Solvent

|

|

|

|

yes

|

|

Mineral oil

|

Solvent

|

|

|

|

yes

|

|

nitric acid

|

Acid

|

|

|

|

yes

|

|

Non-silicone thermal grease

|

Thermal grease

|

yes

|

yes

|

|

yes

|

|

Petroleum

|

Oil / Lubricants

|

|

|

|

|

|

Polycarbonate (pC)

|

Structural plastic

|

yes

|

|

|

|

|

Polyethylene

|

Rubber /plastic sealant

|

yes

|

|

|

|

|

Polypropylene (pp)

|

Structural plastic

|

yes

|

|

|

|

|

Polystyrene (GppS)

|

Structural plastic

|

yes

|

|

|

|

|

Potassium hydroxide

|

alkali

|

|

|

|

yes

|

|

silicone oil

|

Oil / Lubricants

|

|

|

|

yes

|

|

sodium hydroxide

|

alkali

|

|

|

|

yes

|

|

Sulfuric acid

|

Acid

|

|

|

|

yes

|

|

Tetrachloromethane

|

Solvent

|

|

|

|

yes

|

|

tetradecy lamine

|

|

|

|

|

yes

|

|

Heat transmission grease(silicon)

|

Thermal grease

|

yes

|

yes

|

|

|

|

Tropical pass (with or without

|

Thermal grease

|

yes

|

yes

|

|

|

|

Toluene

|

Solvent

|

|

|

|

yes

|

|

Trimethyl hexamethylene diamine

|

|

|

|

|

yes

|

|

Xylene

|

Solvent

|

|

|

|

yes

|