1. Application

2.External dimensions and equivalent circuit

3.level and characteristics

3-1.Absolute maximum rating

3-2. Optical characteristics

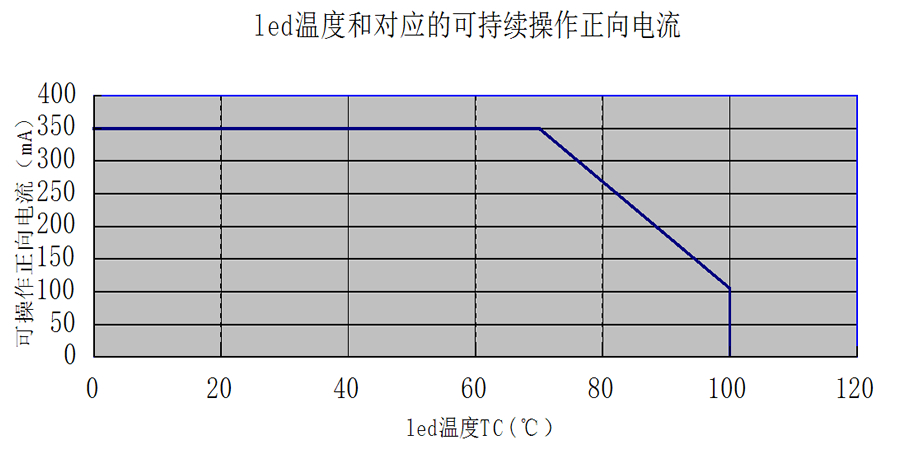

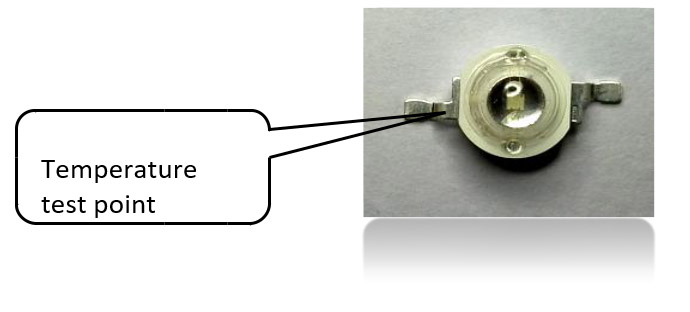

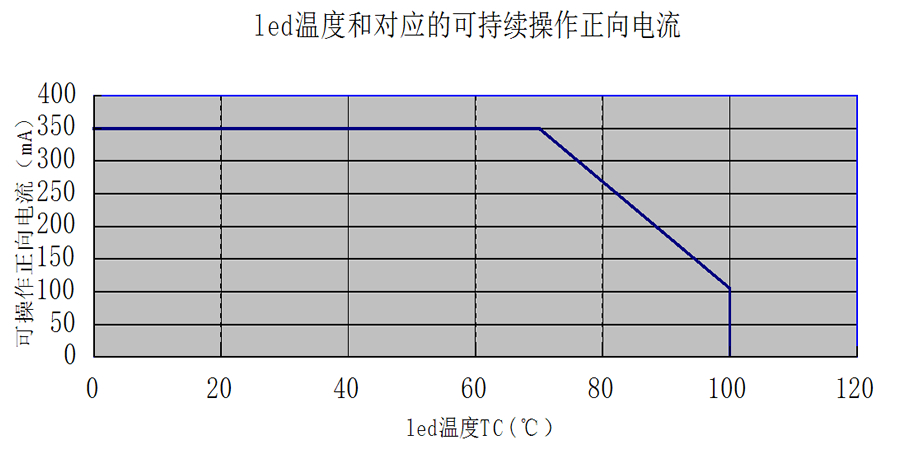

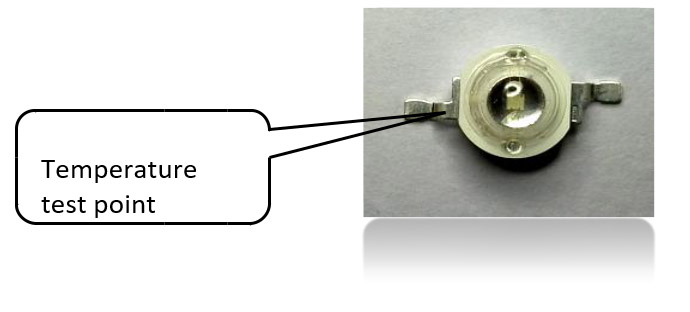

3-3.Derating curve

3-4.Characteristics chart (TYP)

4. Reliability

4-1. Testing items and testing conditions

4-2. Failure criteria

5.Checking project and poor standards

6. Warning

1. Application: decoration, lighting

3W led

This specification applies only to models of imitation Luminus 3W full color

Unit:mm All unlabeled tolerance:±0.2mm

3.Classification and characteristics

3-1.Absolute maximum rating

|

Project

|

Symbol of unit

|

Value

|

Unit

|

|

Max power

|

P

|

1.1

|

W

|

|

Positive direct-current

|

IF

|

350

|

mA

|

|

Negative direct-current

|

VR

|

5

|

V

|

|

Working temperature

|

TOPR

|

-30~+80

|

℃

|

|

Storage temperature

|

TSTG

|

-35~+80

|

℃

|

1,Max power and positive current mean the maximum setting value of the bottom temperature of led light source by using the appropriate heat sink .

2, Originally connection error and off-limits voltage may damage 3W RGB LED

3, Different temperatures,corresponding temperature test point on the next, said 3W RGB LED should operate follow derating curve on the next.

3-2.Optical characteristics: Tc=25 ℃,IF=350mA

|

Project

|

min

|

TYP

|

Max

|

unit

|

|

Red Positive DC voltage(VF)

|

2.0

|

2.2

|

2.4

|

V

|

|

Green Positive DC voltage(VF)

|

3.0

|

3.2

|

3.4

|

V

|

|

Blue Positive DC voltage(VF)

|

3.0

|

3.2

|

3.4

|

V

|

|

R Flux(Φ)

|

40

|

45

|

50

|

lm

|

|

G Flux (Φ)

|

90

|

105

|

115

|

lm

|

|

B Flux (Φ)

|

15

|

20

|

25

|

lm

|

|

R wave length(λd)

|

615

|

620

|

630

|

nm

|

|

G wave length(λd)

|

515

|

520

|

530

|

nm

|

|

B wave length(λd)

|

460

|

465

|

470

|

nm

|

3-3.Derating curve:

Note : In order to keep the temperature below the rated , you should make sure that the radiator has enough heat dissipation performance.

Module testing temperature point:

Reliability

Reliability will meet the following items

4-1. Testing items and testing conditions

|

No.

|

Testing projects

|

Testing conditions

|

Number of samples

|

Failure number

|

|

1

|

High and low impact

|

25℃(30min)+100℃(30min)→25℃(30min)-35℃(30min),100cycles

|

10

|

0

|

|

2

|

High temperature storage

|

+100℃,100h

|

10

|

0

|

|

3

|

Cryogenic storage

|

-35℃,100h

|

10

|

0

|

|

4

|

High temperature and high humidity storage

|

T=+60℃,RH>=90%,100h

|

10

|

0

|

|

5

|

High-temperature operation

|

T=+80℃,IF=350mA,100h

|

10

|

0

|

|

6

|

Low temperature operation

|

T=-30℃,IF=350mA,100h

|

10

|

0

|

|

7

|

Operating temperature and humidity

|

T=+60℃,RH>=90%,IF=350mA,100h

|

10

|

0

|

4-2. Failure criteria:

|

No.

|

Parameter

|

Failure criteria

|

|

1

|

Ray radiation

|

LED No radiation

|

5. Checking projects and unqualified standards

|

No.

|

Project

|

unqualified standards

|

The main unqualified

|

|

1

|

Radiation

|

No Illumination(LED No radiation)

|

unqualified secondary

|

|

2

|

Electronics - optical properties

|

Out of specification (Positive voltage, flux and color coordinate range)

|

The main unqualified

|

|

3

|

External dimensions

|

Does not match with the specified size (as shown in the second page of the external dimensions and tolerances)

|

|

4

|

Exterior

|

Foreign body, Scratches or light emitting range 1mm in diameter bubbles

Emitting a wide range 0.2mm 2.5mm fiber length. Foreign body connection end

Substrate flash: Exceeds the predetermined size

|

6. Warning

Storage conditions:Please observe the following conditions:

*Before opening: the temperature is 5 ~ 30 ℃, relative humidity less than 60%. (After opening the led light source should be used within 15 days.)

*After opening: the temperature is 5 ~ 30 ℃, Relative humidity less than 60%. (Solder within 24 hours)

*After opening the 3W RGB LED should be placed in waterproof packaging alumina absorbent material (Silicone)

*Avoid contacting with corrosive gases. Exposure will damage the electrode surface, it will affect the solder.

②Using conditions:

Any of the following conditions are not designed for this product.

If you use the product in any of the following conditions, please make sure its normal performance and reliability.

*Place where is moist or has dew、cream、salt air、 corrosive gases(C1, H2S, NH3, SO2, NOX, etc.)

*Under direct sunlight, outdoor exposure, dusty place. Water, oil, organic solvents and liquid medical.

③If the led light beyond the prescribed forward current, There may damage led chip lamp beads or Or there is the phenomenon of burning black.

Please use the appropriate heat sink,in order to avoid Led light source has excessive heat.

④Installation:

If installation errors, There will be a short crack plate、high temperature heat or other adverse conditions.Please pay special attention to the installation method. For more information, please refer to the following installation considerations:

*With thermal plastic, sheet or special connectors to install the heat sink. If using only thermal plastic or sheet, please check the validity and reliability before installation. 3W RGB LED may extinguish because of the heat problem, abnormal temperature rise could lead to dire consequences, including equipment damage, solder off, and smoke phenomenon.

*When the led is installed mechanically,note the failure due to withstand pressure

*Avoid uneven plate.

*Recommending highly heat adhesive plate,in order to effectively dissipate heat

*Please focus early and long-term on color changing. 3W RGB LED will changes in light emitted and the light color cause by reflected back changing.

⑤LED tension :

LED surface is limited by the mechanical tension. Putting pressure on the outer lens LED can cause Colloids and internal damage. Don’t apply pressure to the lens surface of the component.

⑥Connection method:

If adopting welding method, please follow the following methods:

*Using anti-static automatic temperature soldering iron(the maximum temperature is 380 ℃), every place no more than 3 seconds.

*Welding across the full pad and soldering should be full.

*Avoid touching the lens portion solder.

*3W RGB LED is not suitable for reflow soldering.

*Please smooth welding.

*Please contact of each electrode to prevent colloidal instability.

⑦Static electricity:

This product is sensitive to static electricity, take measures to deal with . If it is necessary, please install a protective circuit.

⑧Starting method

* When the led light at work, can not be applied any reverse voltage to led light.

*When not working, any reverse and forward voltage can not be applied to the module.

*Energy supply is recommended to use constant current driving power.

⑨Clean

*If lens surface has impurities,try to use more soft muslin wipes. Avoid scratching the lens and please staining with a soft muslin volatile ethanol for cleaning.

⑩ Security

*If a large current through, there will be serious consequences. Such as abnormal temperature, smoke, fire, etc. Careful handling large current and voltage.

*If applying soldering connection methods to work,it may lead to thermal damage. Please choose wires carefully in order to prevent short circuit or leakage caused by the contact.

*Please ensure that the equipment used in compliance with national safety standards and regulations

*User should wear sunglasses before view the working led light and never look 3W RGB LED directly. In addition, the operator should not watch the reflected 3W RGB LED more than 60 seconds.