Features

Small package with high efficiency

Low voltage operation, Instant light

Long operation life

Lead free product

RoHS compliant RoHS

Applications

Traditional lighting replacement

Ordinary lighting

Indoor&Outdoor sign board back light

Architectural / Decorative Lighting

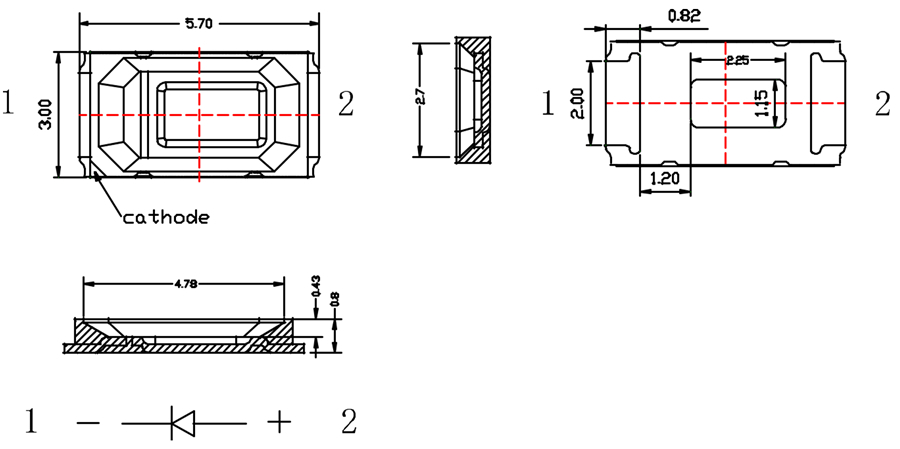

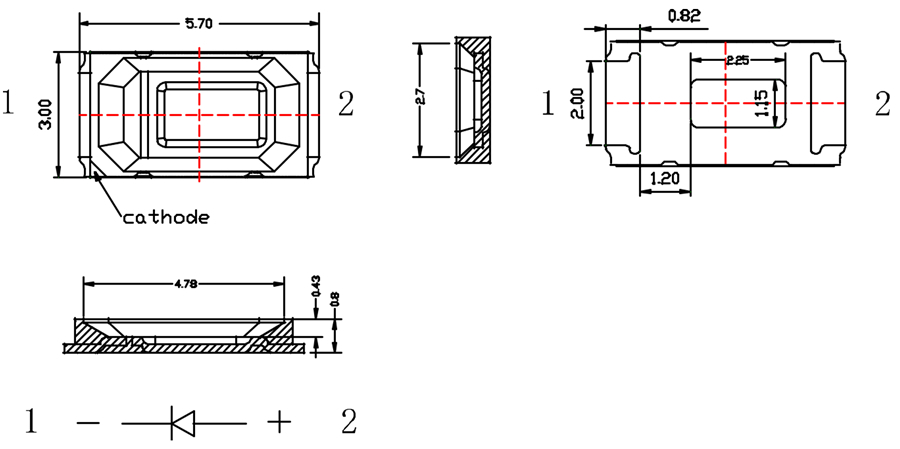

Package Dimensions

Notes:

1. All dimensions are in mm 。

2. Tolerance is ±0.15mm unless otherwise noted. ,±0.15 。

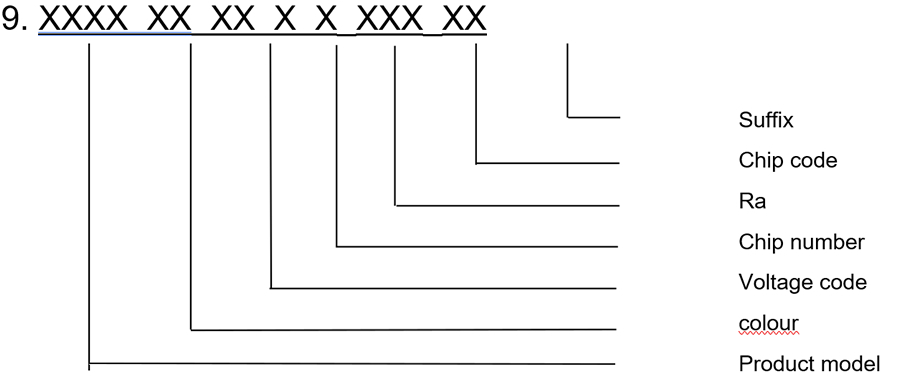

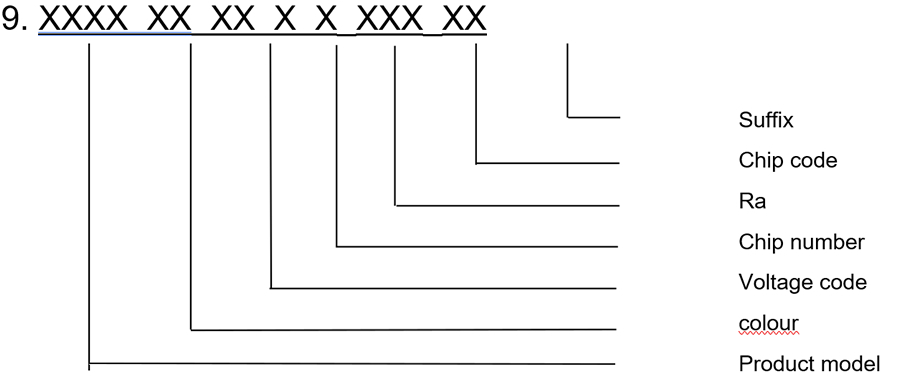

Product coding rules

Electro Optical Characteristics (TA=25℃)

|

Parameter

|

Test Condition

|

Symbol

|

Min

|

Typ

|

Max

|

Unit

|

|

|

|

|

|

|

|

|

|

Forward Voltage

|

IF=150mA

|

VF

|

2.8

|

---

|

3.4

|

V

|

|

|

|

|

|

|

|

|

|

|

|

Reverse Current

|

VR=-5V

|

IR

|

---

|

---

|

10

|

μA

|

|

|

|

|

|

|

|

|

|

|

|

View Angle

|

IF=150mA

|

2θ1/2

|

---

|

120

|

---

|

deg.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Electrostatic Discharge

|

HBM

|

ESD

|

---

|

---

|

2000

|

V

|

|

|

|

|

|

|

|

|

|

|

|

Color tolerance

|

IF=150mA

|

SDCM

|

---

|

---

|

5

|

---

|

Absolute Maximum Ratings (TA=25℃)

|

Parameter

|

Symbol

|

|

Rating

|

Unit

|

|

|

|

|

|

|

|

|

Forward Current

|

|

IF

|

|

150

|

mA

|

|

|

|

|

|

|

|

Pulse Forward Current *1

|

IFP

|

|

225

|

mA

|

|

|

|

|

|

|

|

|

Power Dissipation

|

|

PO

|

|

500

|

mW

|

|

|

|

|

|

|

|

|

Reverse voltage

|

|

VR

|

|

5

|

V

|

|

|

|

|

|

|

|

Work pin temperature *2

|

Topr

|

|

-40 to +105

|

℃

|

|

|

|

|

|

|

|

Storage Temperature Range

|

Tstg

|

|

-40 to +85

|

℃

|

|

|

|

|

|

|

|

Junction Temperature

|

Tj

|

|

125

|

℃

|

|

|

|

|

|

|

|

Soldering Temperature

|

Tsld

|

|

260℃ for 10sec

|

NOTE1:Frequency 10KHz, duty ratio ≤10% 10KHz ,≤10%

NOTE2:The maximum allowable temperature of the pin depends on the current value applied to LED, and the reference chart of “forward current and pin temperature”is required.

LED ,“”。

Mass Production List (IF=150mA;TA=25℃)

|

Part NO.

|

Color

|

(

)

|

|

()

|

|

|

( )

|

|

(

|

)

|

()

|

|

|

Rendering

|

CCT

|

K

|

CCT

|

Φ

|

lm

|

|

index

|

CCT K

|

|

K

|

|

lm

|

Φ

|

|

Min

|

Typ

|

Max

|

|

Min

|

Max

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9.5730W1V21F_J04

|

80

|

|

6500

|

|

|

|

65

|

75

|

|

|

|

|

|

|

|

|

|

|

|

9.5730W1V21F_J04

|

80

|

|

5700

|

|

|

|

65

|

75

|

|

|

|

|

|

|

|

|

|

|

|

9.5730W1V21F_J04

|

80

|

|

5000

|

|

|

|

65

|

75

|

|

|

|

|

|

|

|

|

|

|

|

9.5730W2V21F_J04

|

80

|

|

4000

|

|

|

|

65

|

75

|

|

|

|

|

|

|

|

|

|

|

|

9.5730W3V21F_J04

|

80

|

|

3500

|

|

|

|

65

|

75

|

|

|

|

|

|

|

|

|

|

|

|

9.5730W3V21F_J04

|

80

|

|

3000

|

|

|

|

60

|

70

|

|

|

|

|

|

|

|

|

|

|

|

9.5730W3V21F_J04

|

80

|

|

2700

|

|

|

|

60

|

70

|

Note: The test error

VF: ±3% XY : ±0.005 Φ : ±10% Ra:-1+8

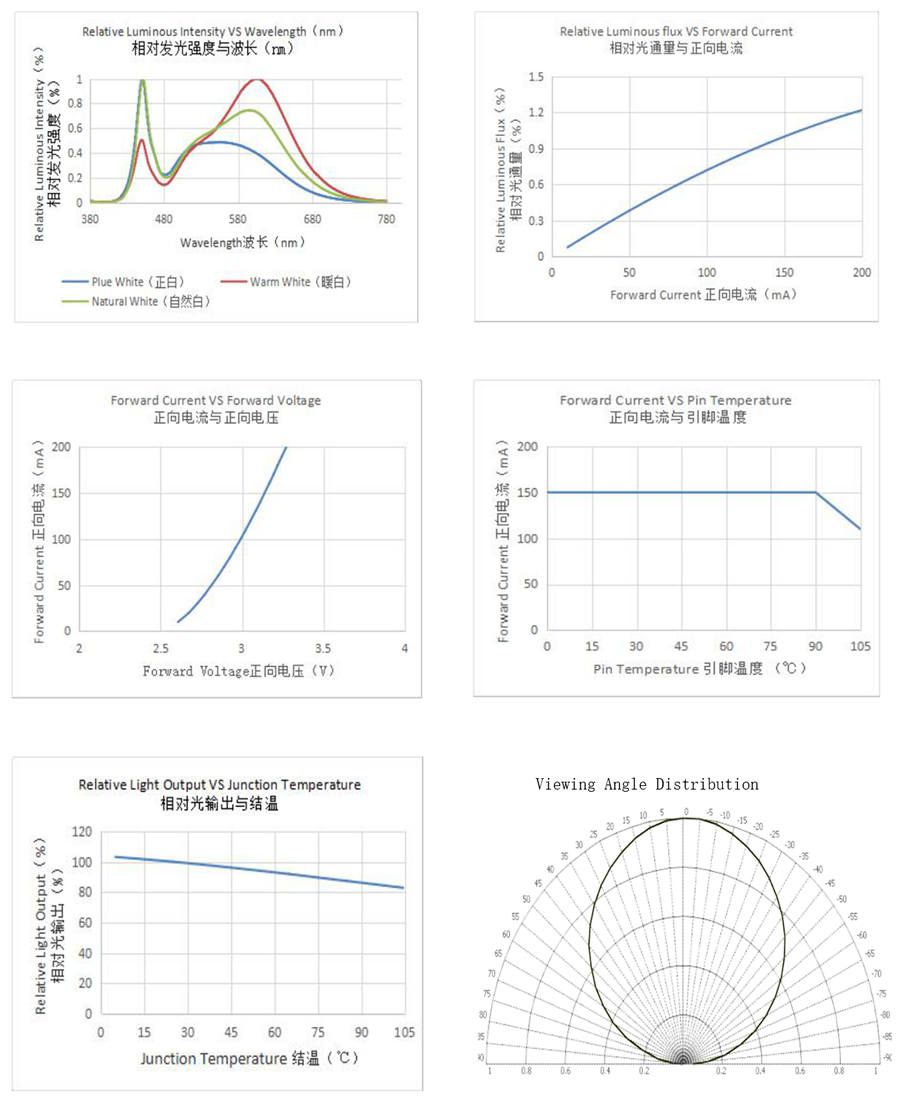

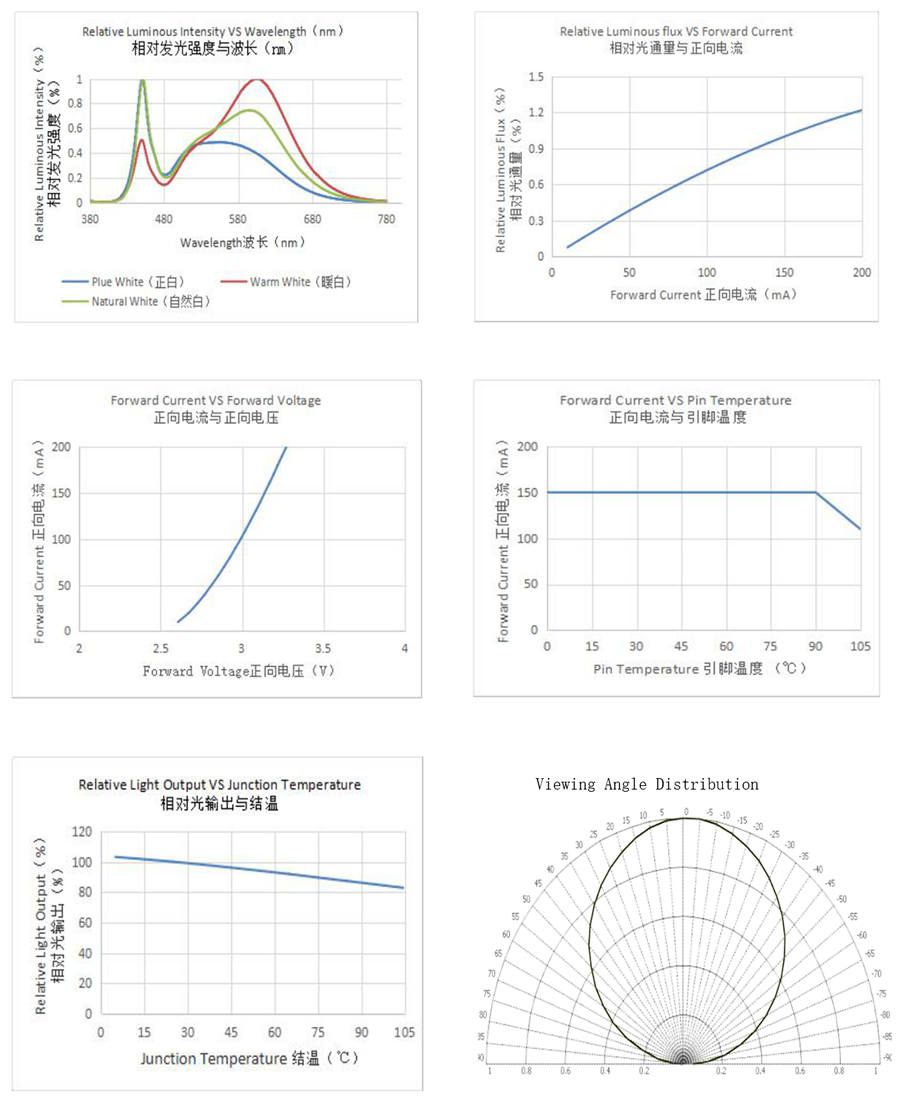

Typical Electrical/Optical Characteristic Curves(IF=150mA;TA=25℃)

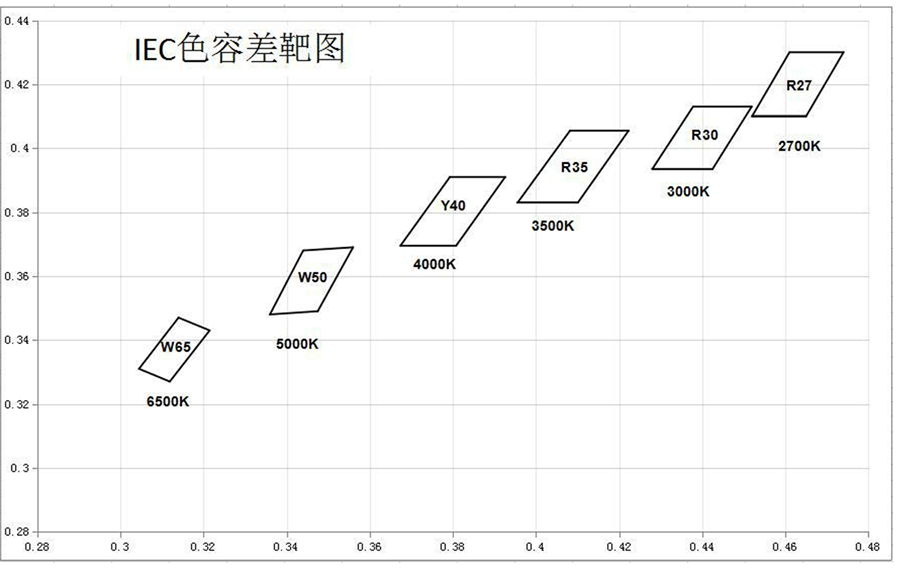

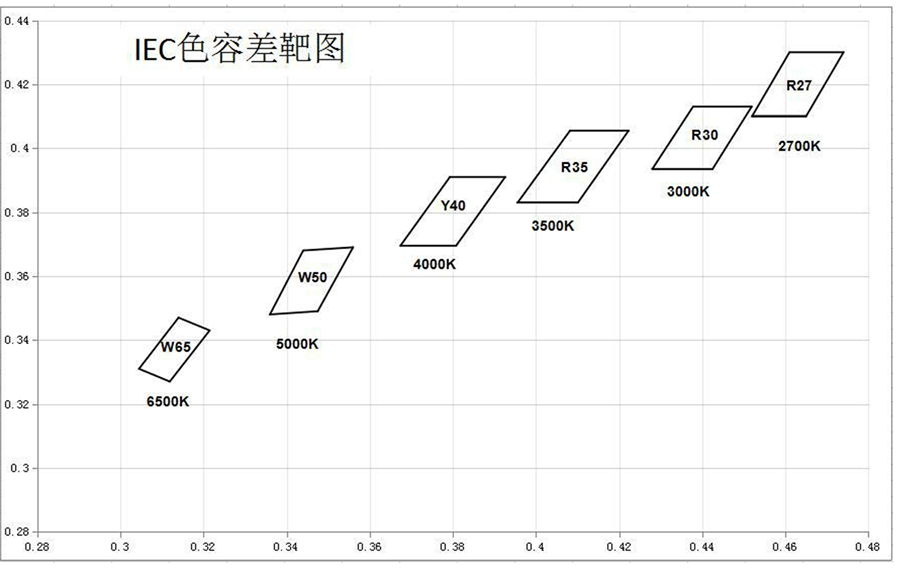

CIE Chromaticity Diagram:(IF=150mA;TA=25℃)

CIE

Color Rank :(IF=150mA;TA=25℃) Bin

|

CODE

|

CCT

|

X

|

Y

|

|

|

|

|

|

|

|

|

0.461

|

0.43

|

|

|

|

|

|

|

R27

|

2700K

|

0.452

|

0.41

|

|

|

|

|

0.465

|

0.41

|

|

|

|

|

|

|

|

|

|

|

|

0.474

|

0.43

|

|

|

|

|

|

|

|

|

|

|

|

CODE

|

CCT

|

X

|

Y

|

|

|

|

|

|

|

|

|

0.4082

|

0.4055

|

|

|

|

|

|

|

R35

|

3500K

|

0.3956

|

0.383

|

|

|

|

|

0.4101

|

0.383

|

|

|

|

|

|

|

|

|

|

|

|

0.4223

|

0.4055

|

|

|

|

|

|

|

|

|

|

|

|

CODE

|

CCT

|

X

|

Y

|

|

|

|

|

|

|

|

|

0.344

|

0.368

|

|

|

|

|

|

|

W50

|

5000K

|

0.336

|

0.348

|

|

|

|

|

0.3475

|

0.349

|

|

|

|

|

|

|

|

|

|

|

|

0.356

|

0.369

|

|

|

|

|

|

|

CODE

|

CCT

|

X

|

Y

|

|

|

|

|

|

|

|

|

0.4378

|

0.413

|

|

|

|

|

|

|

R30

|

3000K

|

0.428

|

0.3935

|

|

|

|

|

0.4425

|

0.3935

|

|

|

|

|

|

|

|

|

|

|

|

0.4519

|

0.413

|

|

|

|

|

|

|

|

|

|

|

|

CODE

|

CCT

|

X

|

Y

|

|

|

|

|

|

|

|

|

0.3793

|

0.391

|

|

|

|

|

|

|

Y40

|

4000K

|

0.3674

|

0.3695

|

|

|

|

|

0.3808

|

0.3695

|

|

|

|

|

|

|

|

|

|

|

|

0.3926

|

0.391

|

|

|

|

|

|

|

|

|

|

|

|

CODE

|

CCT

|

X

|

Y

|

|

|

|

|

|

|

|

|

0.314

|

0.347

|

|

|

|

|

|

|

W65

|

6500K

|

0.3045

|

0.331

|

|

|

|

|

0.3119

|

0.327

|

|

|

|

|

|

|

|

|

|

|

|

0.3215

|

0.343

|

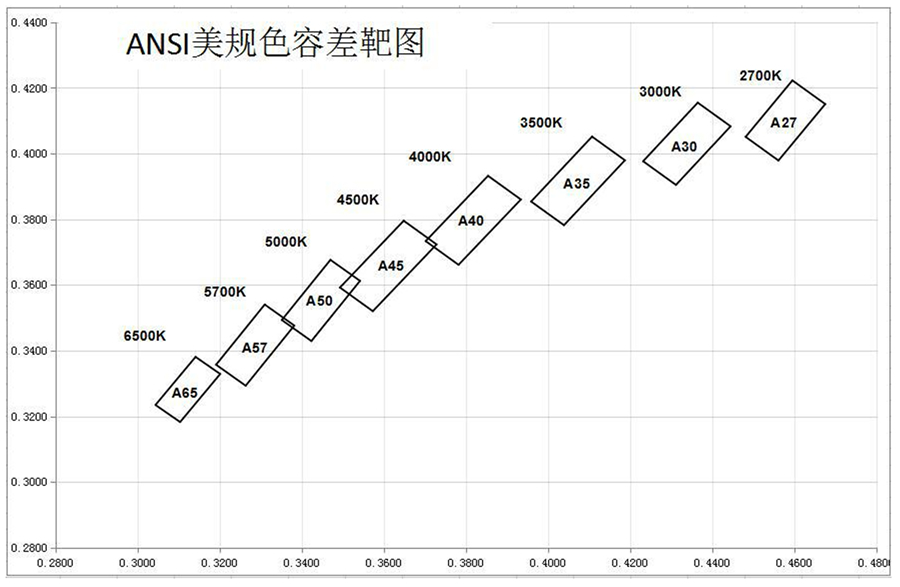

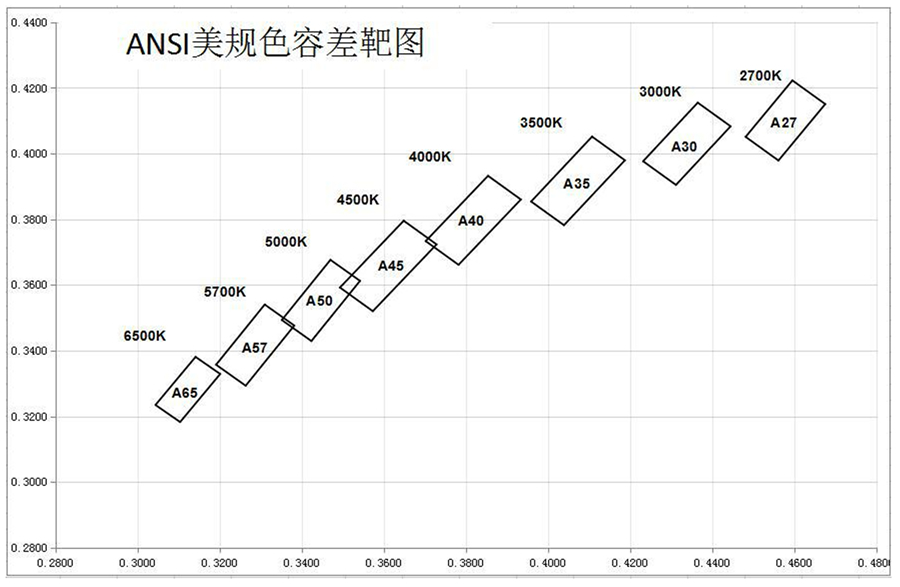

CIE Chromaticity Diagram:(IF=150mA;TA=25℃)

CIE

Color Rank :(IF=150mA;TA=25℃) Bin

|

CODE

|

CCT

|

X

|

Y

|

|

|

|

|

|

|

|

|

0.4595

|

0.4223

|

|

|

|

|

|

|

A27

|

2700K

|

0.4481

|

0.4051

|

|

|

|

|

0.4561

|

0.3979

|

|

|

|

|

|

|

|

|

|

|

|

0.4675

|

0.4151

|

|

|

|

|

|

|

|

|

|

|

|

CODE

|

CCT

|

X

|

Y

|

|

|

|

|

|

|

|

|

0.4107

|

0.4052

|

|

|

|

|

|

|

A35

|

3500K

|

0.3959

|

0.3854

|

|

|

|

|

0.4039

|

0.3782

|

|

|

|

|

|

|

|

|

|

|

|

0.4187

|

0.3980

|

|

|

|

|

|

|

|

|

|

|

|

CODE

|

CCT

|

X

|

Y

|

|

|

|

|

|

|

|

|

0.3649

|

0.3796

|

|

|

|

|

|

|

A45

|

4500K

|

0.3493

|

0.3592

|

|

|

|

|

0.3573

|

0.3520

|

|

|

|

|

|

|

|

|

|

|

|

0.3729

|

0.3724

|

|

|

|

|

|

|

|

|

|

|

|

CODE

|

CCT

|

X

|

Y

|

|

|

|

|

|

|

|

|

0.3310

|

0.3541

|

|

|

|

|

|

|

A57

|

5700K

|

0.3192

|

0.3357

|

|

|

|

|

0.3264

|

0.3293

|

|

|

|

|

|

|

|

|

|

|

|

0.3382

|

0.3477

|

|

|

|

|

|

|

CODE

|

CCT

|

X

|

Y

|

|

|

|

|

|

|

|

|

0.4365

|

0.4155

|

|

|

|

|

|

|

A30

|

3000K

|

0.4231

|

0.3977

|

|

|

|

|

0.4311

|

0.3905

|

|

|

|

|

|

|

|

|

|

|

|

0.4445

|

0.4083

|

|

|

|

|

|

|

|

|

|

|

|

CODE

|

CCT

|

X

|

Y

|

|

|

|

|

|

|

|

|

0.3854

|

0.3932

|

|

|

|

|

|

|

A40

|

4000K

|

0.3702

|

0.3734

|

|

|

|

|

0.3782

|

0.3662

|

|

|

|

|

|

|

|

|

|

|

|

0.3934

|

0.3860

|

|

|

|

|

|

|

|

|

|

|

|

CODE

|

CCT

|

X

|

Y

|

|

|

|

|

|

|

|

|

0.3470

|

0.3677

|

|

|

|

|

|

|

A50

|

5000K

|

0.3352

|

0.3493

|

|

|

|

|

0.3424

|

0.3429

|

|

|

|

|

|

|

|

|

|

|

|

0.3542

|

0.3613

|

|

|

|

|

|

|

|

|

|

|

|

CODE

|

CCT

|

X

|

Y

|

|

|

|

|

|

|

|

|

0.3142

|

0.3381

|

|

|

|

|

|

|

A65

|

6500K

|

0.3044

|

0.3235

|

|

|

|

|

0.3104

|

0.3183

|

|

|

|

|

|

|

|

|

|

|

|

0.3202

|

0.3329

|

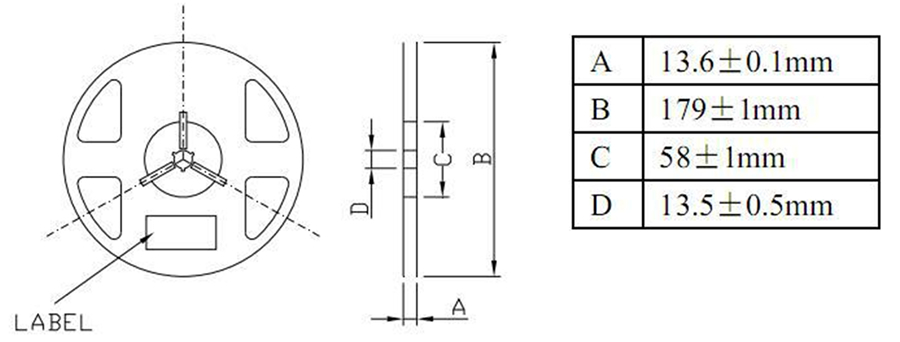

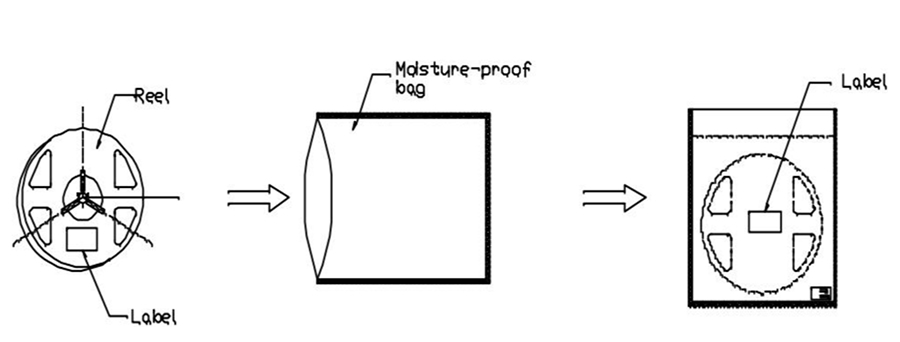

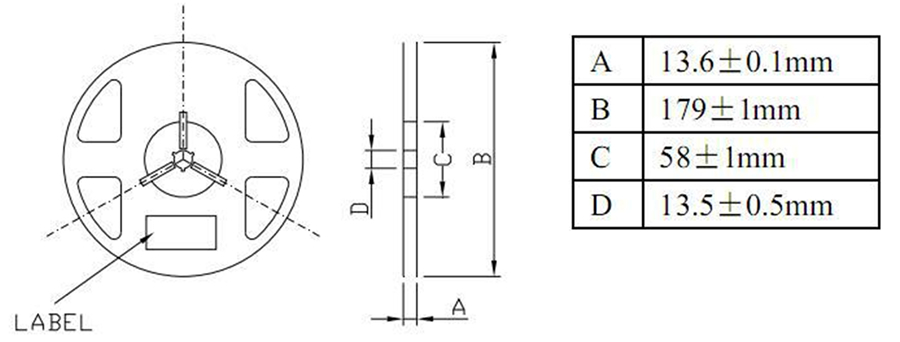

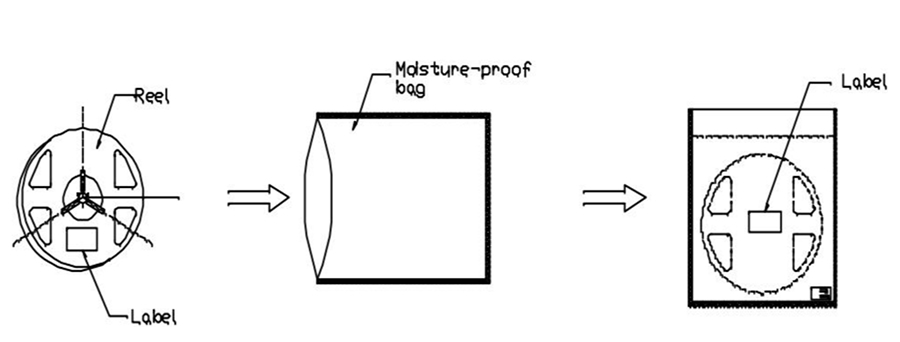

Packaging Specifications

Dimensions of Tape

Dimensions of Reel

Packaging specifications

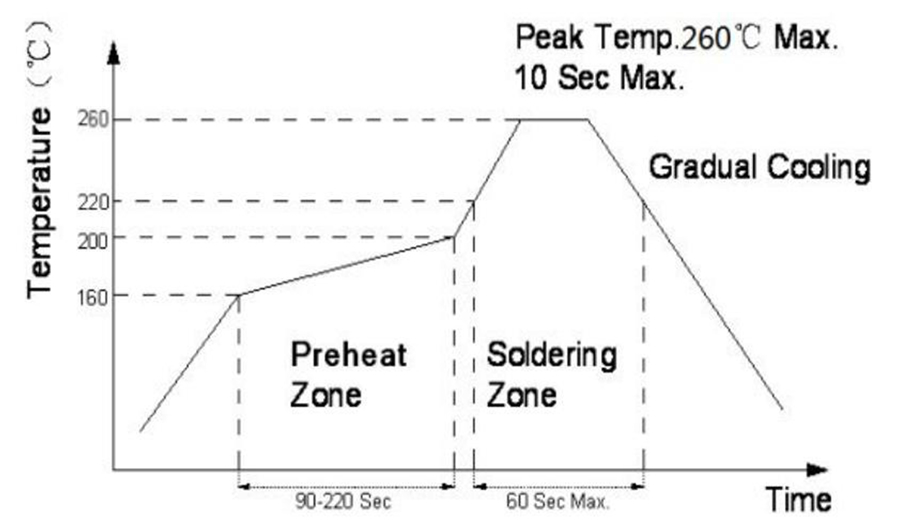

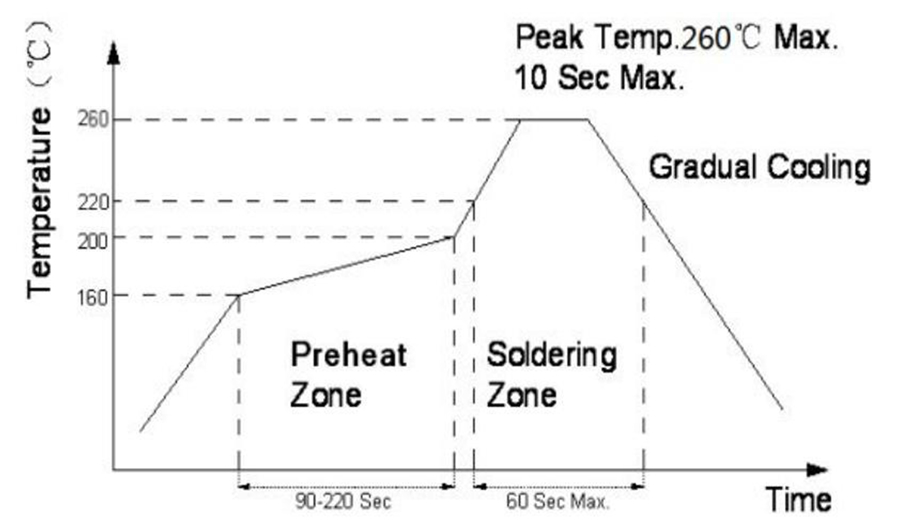

SMT Reflow Soldering Instructions SMT

1.Reflow soldering should not be done more than two times.

2.When welding, the material is heated and can not press the surface of the colloid.

CAUTIONS

1,The encapsulated material of the 5730 smd LEDs is silicone ,so the surface of 5730 smd LED colloid is softer, forcing the colloid surface hard will affect the reliability of LED.

2,Material confirmation. Whether the LED Bin specifications of the material are consistent , such as whether VF, XY, brightness and so on belong to the same specification, the same specification should be used together, if not the same specification 5730 LED is applied to the same object, it should be evaluated first, (if different VF or XY cast together may produce difference in brightness or color).

2、。 LED Bin , VF、XY、 LED ,( VF XY )

3,Packaging and storage

3.1 Before opening packaging, avoid moisture entry into LED. 5730 SMD series LED is suggested to be stored in a drying cabinet with built-in desiccant. The storage environment is 5-30 centigrade, no more than 50% humidity. If storage time is over 3 months, LED needs to be re dehumidifying (65 degrees centigrade for more than /24 hours).

3.2 Open the precautions after packing. LED is a surface mount. When the 5730 smd LED is welded, the internal separation of 5730 LED may occur. The luminescence efficiency is affected and the luminance decreases or the color variation. The

following are the matters to be paid attention to:

A,After opening the package, welding should be completed as soon as possible (within 12 hours).

B,The remaining materials are sealed or placed in an environment of 5~40 C and no more than 30% humidity.

C,If the open package is more than 24 hours (< 168 hours) or the humidity card is changed from blue to pink, LED needs to be dehumidifying again (65 degrees centigrade for more than /24 hours). If the package is opened for more than 168 hours, it is necessary to dismantle the tape and remove the moisture at 150℃ /2h.

3.3,5730 smd LED electrode and bracket are made of silver plated copper alloy. The silver layer on the surface is easy to be affected by corrosive gases. Please avoid contacting with corrosive environment to cause 5730 LED discoloration, so as to avoid the poor weldability of LED and influence the photoelectric performance. Avoid sudden changes in temperature and humidity of the environment, especially under high humidity environment, easy to produce water vapor condensation.

4,Electrostatic protection. 5730 smd LED is a chip sensitive electronic component. Various measures should be taken to avoid static electricity, such as wearing an electrostatic bracelet or anti-static gloves during use. All devices, equipment and instruments should be well grounded.